In response to the demand for advanced materials in the era of 5G technology and stringent pressing requirements in the electronics industry, our dedicated R&D team has developed the high-temperature 260℃resistant cushioning material called NAWES MAT™. NAWES MAT™ press pads composed of premium glass fiber and polymer composite, offers more enhanced temperature resistance, stability, eco-friendliness, energy efficiency, cost-effectiveness, and easily operated, can be reused multiple times.

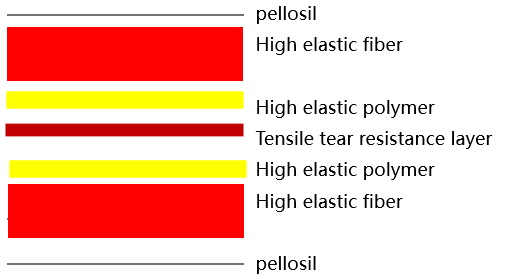

The FPC Special High Temperature And Pressure Buffer Material is a cutting-edge solution designed for the demanding requirements of the soft and hard composite board industry. Composed of high-elastic fibers and polymers, this product offers superior cushioning performance compared to traditional kraft paper and silicone pads. It is engineered to withstand extreme temperatures up to 260°C, making it an ideal choice for high-pressure lamination processes.

| Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations | |

| Dark red cushion ( Suitable for soft board, soft and hard combination ) board | ★ | ★ | ❏ | ❏ | ❏ | ★ | ★ | 100-200 |

| Bullskin paper | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the pressing process of soft board and soft and hard bonding board. This product has good thermal conductivity and can solve the problems of high and low difference in soft and hard bonding board and lack of glue in hard board.

High-Temperature Resistance: Capable of operating at 260°C for extended periods without carbonization or brittleness, ensuring durability in high-heat environments.

Superior Cushioning Performance: Provides excellent heat conduction uniformity, stable compression shrinkage, and consistent expansion coefficients, ensuring reliable performance in every use.

Durability and Safety: With a lifespan of 100-200 presses, it is flame retardant, non-toxic, odorless, and dust-free, making it safe for both operators and the environment.

Eco-Friendly and Cost-Effective: Its reusable design reduces waste, while its energy-saving properties lower operational costs, aligning with modern environmental standards.

Customizable Thickness: Available in thicknesses ranging from 1.0mm to 10mm, it can be tailored to meet specific customer requirements.

High-Quality Cost Performance: Combining advanced technology with competitive pricing, the FPC Special High Temperature And Pressure Buffer Material delivers exceptional value for industrial applications.

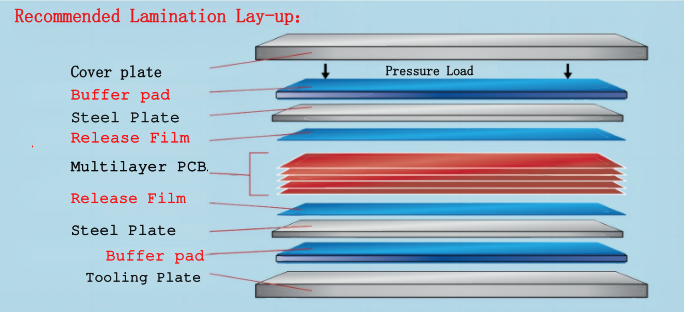

The FPC Special High Temperature And Pressure Buffer Material features a multi-layered design optimized for middle-layer physical buffering. It is compatible with both manual and automated operations, replacing multiple layers of kraft paper with a single, high-performance sheet. This innovative structure ensures consistent pressure distribution and enhances overall production efficiency.

| Compare Item 1 | Navies pad | Bullskin paper | Compare Item 2 | Navies pad | Bullskin paper |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

Our company offers tailored cost-saving solutions for customers, enabling a 10-20% reduction in expenses compared to traditional kraft paper. By switching to the FPC Special High Temperature And Pressure Buffer Material, businesses can achieve significant operational efficiencies while maintaining high-quality standards.

NAWES MAT™ cushion pad is one of Huanyuchang's representative products.It is reported that this product was born with the mission of 'revolutionizing the life of traditional kraft paper'.

NAWES MAT™ cushioning pads are suitable for lamination processes such as PCB, FPC, and CCL. They are the best products to replace kraft paper. They have more stable performance, are more resistant to high temperatures, are more environmentally friendly, and can be produced automatically, reducing costs and improving benefits for customers.

NAWES MAT™ cushion pad is a product with excellent comprehensive performance and high stability that has been verified by Chinese and foreign engineering and technical personnel after several years of research, analysis and improvement based on the introduction of similar foreign products, and after a long period of production and application.

NAWES MAT™ press pads composed of premium glass fiber and polymer composite, offers more enhanced temperature resistance, stability, eco-friendliness, energy efficiency, cost-effectiveness, and easily operated, can be reused multiple times compared to kraft paper and silicone pads.

NAWES MAT™ cushion pad is not easy to harden and become brittle; it also has the advantages of stable heat transfer performance, good heat conduction uniformity, stable heating rate, and relatively stable shrinkage after lamination. In addition, the product is tear-resistant, pressure-resistant and flame-retardant, can be reused 300-500 times (traditional kraft paper can only be reused 3-5 times), is non-toxic and odorless, and does not produce dust, gas, precipitates, etc. that may cause adverse effects. And high cost performance is the biggest advantage of this product! Compared with similar international products, the price of Huanyuchang's NAWES MAT™ cushion pad is significantly lower. It is understood that a customer company has specially made a cost comparison between traditional kraft paper and NAWES MAT™ cushion pads.

Through calculation, the cost of NAWES MAT™ cushion thin pads is 21.4% lower than that of traditional kraft paper, and the cost of NAWES MAT™ cushion thick pads is 43.3% lower than that of traditional kraft paper.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More