Huanyuchang Electronics is committed to becoming a substrate, semiconductor materials first-class integrated service provider, the company 's core business is to provide customers with high cost-effective consumables materials, solve the pressing, off-type application material solutions.

Huanyuchang has a research and development team composed of university members, focusing on the development of FPC / PCB high-performance composite, hot-pressed materials.

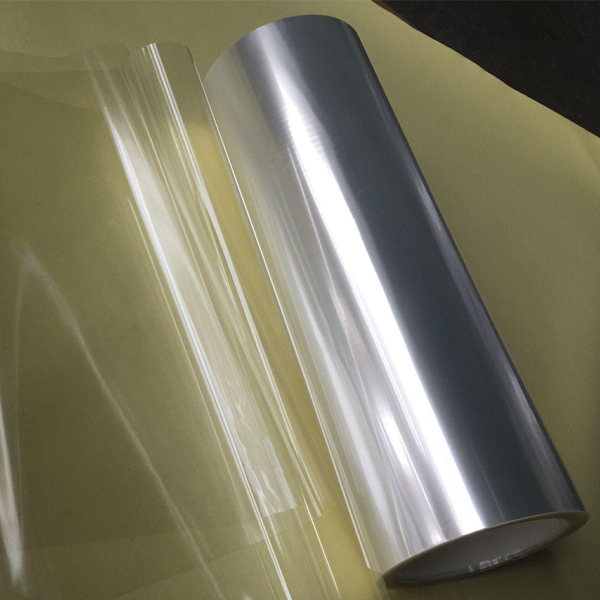

It is suitable for the pressing filling and covering of soft and hard bonding plates in the pressing process of soft and hard bonding plates.

1.better temperature resistance

2.can meet the different soft and hard plate height difference

3.Better dimensional stability after compression

4.can match different specifications of the core layer and size

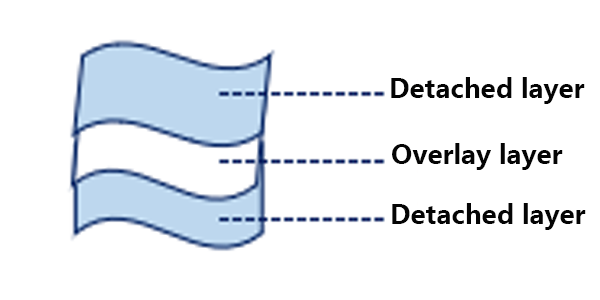

Product name | Thickness | Structure | Color |

three-in-one | 25-500um | three-layer | Matte or smooth |

Three-in-One Conformal Film

This buffer material is specially developed for products with large differences in levels such as multi-layer FPC and Rigid-flex PCB.

1. High temperature resistance, the operating temperature can reach 200℃;

2. Good filling effect;

3. Good release effect and no residue;

4. After lamination, there is no glue residue on the buffer layer, effectively protecting the mirror steel plate from contamination;

5. The overlay operation is simple, greatly reducing employee error rates;

6. No longer restricted by complex and diverse lamination auxiliary materials, automated lamination production can be realized!

Service Guarantee

Our Company service guarantee include the following aspects :

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

Service process assurance : Develop and implement standardized service processes to ensure service quality and efficiency. Continuously improve and optimize the service process according to customer feedback and market changes.

Service security : establish a sound information protection mechanism to protect the security and privacy of customer information. Take the necessary safety measures to ensure the personal and property safety in the service process.

After-sales service guarantee : after the end of the service, continue to provide customers with the necessary support and help to solve possible problems. Establish a customer satisfaction survey mechanism, through regular customer satisfaction surveys, to understand customer evaluation and feedback on services, in order to continuously improve service quality.

Through the above measures, the company can provide a full range of service guarantee to ensure customer satisfaction.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More