Yuchang Electronics is committed to becoming a substrate, semiconductor materials first-class integrated service provider, the company 's core business is to provide customers with high cost-effective consumables materials, solve the pressing, off-type application material solutions.

Huanyuchang has a research and development team composed of university members, focusing on the development of FPC / PCB high-performance composite, hot-pressed materials.

Polyester resin, polyethylene resin, polyester resin

Through polyester resin, polyethylene resin and polyester resin, this product has excellent heat resistance, cushioning property, release property, glue resistance and shrinkage uniformity.

The cushioning material is specially developed for products with large difference between high and low levels, such as multi-layer soft plate, soft and hard bonding plate :

1, high temperature resistance, the use temperature can reach 200 °C ;

2, filling effect is good ;

3. The release effect is good, no residue ;

4.After pressing, there is no residual glue in the buffer layer, which effectively protects the mirror steel plate from pollution.

The superposition operation is simple, which greatly reduces the error rate of employees ;

6, no longer restricted by the complex and diverse pressing auxiliary materials, can realize the automatic laminated production !

project | numerical value | Tolerance | Remarks | ||

dimension | thickness | 190um | ±10% | thickness gauge | |

Length | 500m | ±2m | Meter counter or cutting | ||

Width | 270,520mm | ±2mm | ruler | ||

melting point | outer layer | 210℃ | ±5℃ | melting point apparatus | |

inner layer | 100℃ | ±5℃ | |||

tensile strength | MD | 30MPa | ±5MPa | electronic universal material testing machine | |

TD | 20MPa | ±5MPa | |||

dimensional stability | MD | 2.10% | ≤4% | analyzer | |

TD | 1.70% | ≤2.5% | |||

Density | 1.05g/cm³ | 0.9-1.1g/cm³ |

| ||

Foginess | 3.20% | ±0.5% | Light transmittance haze meter | ||

Glossiness | 125% | ±10% | Gloss meter | ||

Dielectric strength | 65KV/mm | ±5KV/mm | Dielectric strength tester | ||

testing item | Test basis | remark | Test pp model | Pressing conditions |

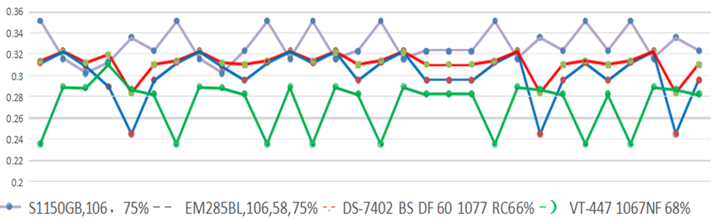

Resistance glue value | actual measurement | Using NoFLowPP The second-dimensional optical measurement of PP overflow after laminating was carried out. | S1150GB,106 ,75%

EM285BL,106,58,75%

DS-7402 BS DF 60 1077 RC66%

VT-447 1067NF 68%

|

temperature:195℃

time:120min

pressure:400PSI

|

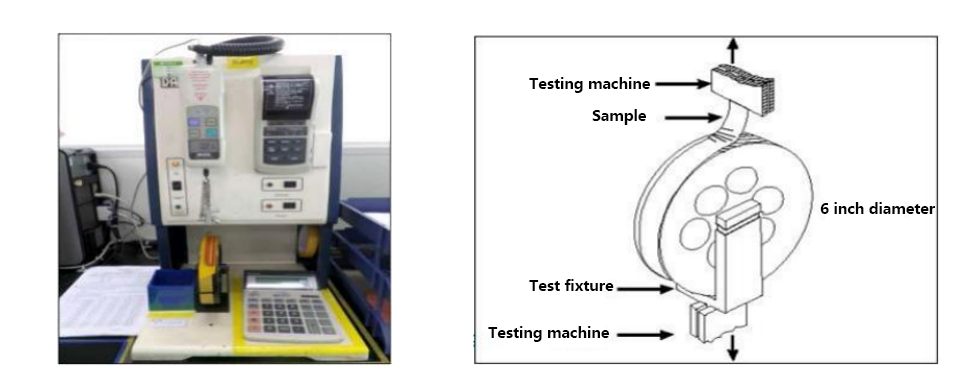

release force | TM-650-2.4.9

| Sampling 25mm * 100mm, with peel strength tester at a speed of 10mm / min, 10N load 180 degrees peel test. | ||

Product shrinkage | TM-650-2.2.4

| The size change of the second-dimensional optical measurement product after pressing is measured. | ||

degree of contamination | actual measurement | CuCl inspection |

1.The resistance value is basically controlled between 0.3mm-0.35mm.

2.Due to the differences in equipment and process among customers, the above data are only for reference.

PP model | specification(Min) | specification(Max) | CPK | sampling method |

S1150GB,106,75%

| 0.3022 | 0.3513

| 3.601 | Each batch of sampling 25 pcs cumulative registration |

EM285BL,106,58,75%

| 0.2452 | 0.3231 | 2.978

| |

DS-7402 BS DF 60 1077 RC66% | 0.2832

| 0.3224 | 5.836

| |

VT-447 1067NF 68%

| 0.2354

| 0.3111 | 2.421 |

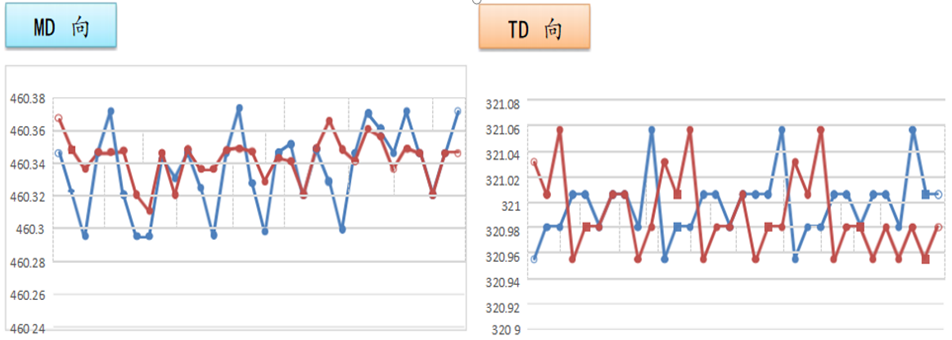

Serial number | Nominal value | Kilometres | Kilometers below | Results analysis | |||||||

Average value | R value | On the upper side % | Lower% | Std Dev | pP | CA | CPK | ||||

MD | 460.32 | 0.138 | -0.138 | 460.335 | 0.078 | 38.2% | -18.4% | 0.0247 | 1.867 | 0.110 | 1.661 |

MD | 460.32 | 0.138 | -0.138 | 460.342 | 0.056 | 33.6% | -7.2% | 0.0131 | 3.511 | 0.156 | 2.963 |

TD | 320.98 | 0.096 | -0.096 | 320.997 | 0.101 | 79.1% | -26.4% | 0.0255 | 1.260 | 0.173 | 1.342 |

TD | 320.98 | 0.096 | -0.096 | 320.990 | 0.101 | 79.1% | -26.4% | 0.0315 | 1.019 | 0.107 | 1.867 |

Pressing dimensional tolerances are controlled according to ± 3 %

Pressing dimensional tolerances are controlled according to ± 3 %

After pressing, 5pnl ( 12 ', ' * 18 ', ' ) was taken to check the contamination of copper surface with Cucl.

product identification number | front(point) | reverse side(point) |

1 | 2 | 0 |

2 | 0 | 1 |

3 | 2 | 1 |

4 | 1 | 0 |

5 | 0 | 0 |

For adverse points with 30 times under the microscope analysis :

project | quantity(point) |

Kraft paper scraps | 5 |

Residual glue | 1 |

Fibers | 1 |

It can be seen from the analysis results. The dirty spots on the copper surface come from poor environment, and BH190 has no residue.

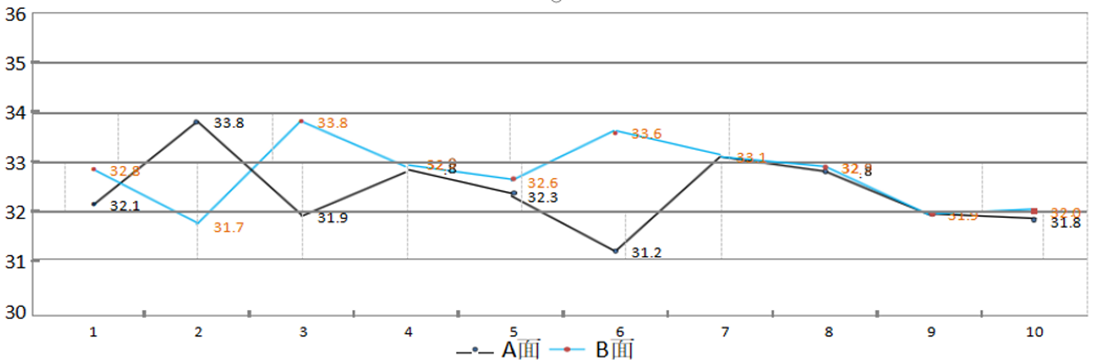

Test method : Test conditions : 5 samples of 25mm × 100mm size were sampled, the samples were fixed on the experimental fixture with double-sided tape, and the samples were peeled off at a speed of 10mm / min with 2kg roller back and forth. The stripping length was within the range of 50mm, and the 10mm fixed into the furniture was not included. The minimum tensile force in the stripping process was observed and recorded, and the test results were finally averaged for comparison.

measured value gf/25mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | mean value |

A side | 32.1 | 33.8 | 31.9 | 32.8 | 32.3 | 31.2 | 33.1 | 32.8 | 31.9 | 31.8 | 32.4 |

B side | 32.8 | 31.7 | 33.8 | 32.9 | 32.6 | 33.6 | 33.1 | 32.9 | 31.9 | 32.0 | 32.7 |

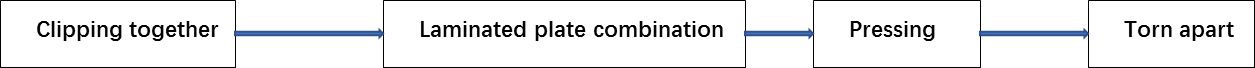

1.cutting

a. cutting size according to customer requirements ;

b. not causing obvious wrinkles of the adhesive film to prevent wrinkles from transferring to the plate surface ;

c.blocking film should not be attached with sundries ;

2.Laminated plate

A. The product should be completely covered by the blocking film when the plate is laminated, and the size of the blocking film should exceed 5mm to prevent the plate from being peeled off when the operation is completed ;

3.Compression

When placed in the press for pressing, it is necessary to confirm that the resistance film is completely flat to prevent the sheet from wrinkling.

operating conditions

Kind of machine | Temperature | Pressure | Preheating time | Forming time |

Fast presses | 180-200℃ | 80-120kgf/cm² | 10-20s | 80-120s

|

Vacuum compressor | 180-200℃ | 15-20kgf/cm² | 10-20s | 80-160s

|

Pressure transmission machine | 180-200℃ | 25-70kgf/cm² | Depending on the product | Depending on the product |

4. Torn apart

When the pressing is completed and the film is torn off, the product needs to be fixed with one hand to prevent the product from being wrinkled due to the different tearing strength of each part.

Storage conditions : room temperature, indoor, dry, avoid corrosion and direct sunlight.

Storage period : 6 months

Non-polluting : Keep the site clean when using to avoid product contamination, otherwise the product is not available

One-time : This product is not reusable when heated and needs to be discarded directly.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More