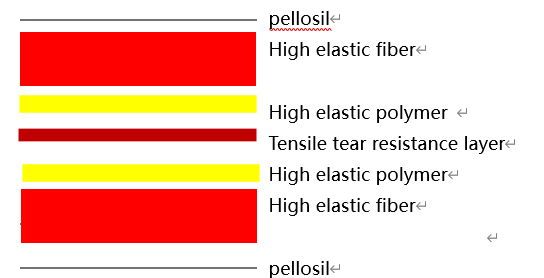

After the introduction of cushioning pads for CCL industry, we have developed the second generation cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation cushioning pad.

Performance Category | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

Red hard pad Suitable for PCB | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-500 |

Red hard pad Suitable for IC-substrate | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-400 |

kraft paper | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the pressing process of soft board and soft and hard bonding board. This product has good thermal conductivity and can solve the problems of high and low difference in soft and hard bonding board and lack of glue in hard board.

1.More resistant to high temperature, can work at 260 ° C for a long time, not carbonized, not brittle ;

2.The buffer effect is good, the heat conduction uniformity is good, the compression shrinkage is stable, the expansion coefficient of the product is stable, and the tear resistance is good ;

3.withstanding pressure ( can be pressed 100 ~ 200 times ), flame retardant, non-toxic and odorless, dust-free and dust-free, good ventilation effect ;

4.Independent research and development, independent production, short production cycle, equipped with faster technical services ;

the production thickness is 1.0 ~ 10mm, which can meet the customer 's needs and record the number of times intelligently ;

6.High quality cost performance.

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

Compare Item 1 | Navies pad | Bullskin paper | Compare Item 2 | Navies pad | Bullskin paper |

Life | ◎ | ◯ | Homogeneity of dielectric layer | ◎ | ◯ |

Pressure buffering | ◎ | ▲ | Impedance controllability | ◎ | ◎ |

Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ▲ |

Pressure transfer stability | ◎ | ◎ | Thick copper adaptability | ◎ | ▲ |

Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

Heat transfer uniformity | ◎ | ▲ | Storage convenience | ◎ | ▲ |

Heat conduction efficiency | ◎ | ◯ | Operation convenience | ◎ | ▲ |

Processing efficiency | ◎ | ◯ | Cleanliness | ◯ | ◎ |

Heat resistance | ◎ | ▲ | Recycling and reuse | ◎ | ▲ |

Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ◯ |

According to the actual situation of customers, our company formulates a cost saving scheme, which can save 10-20 % cost compared with conventional kraft paper according to the current customer base.

Summary

1.Functional characteristics, technological innovation : In order to break the long-term technological monopoly of foreign countries, our company introduced foreign excellent technical products, and together with the Chinese Academy of Sciences through product research, analysis, improvement, experimental verification to obtain a complete technology for making cushions, to solve the domestic pressing cushion production technology gap, the only new material that can replace kraft paper and silicone pad.

2.Low cost : Affected by the global epidemic and international forms, the price of materials in the industry is on the rise, and the cushion can be used repeatedly to meet customer requirements and reduce costs.

3.Environmental protection : Replacing kraft paper and silicone pads can maintain the stability of the ecological environment ( slow down the greenhouse effect and reduce soil erosion ) ; the cushion is composed of high elastic fiber, anti-sticking and high temperature resistant reinforcing material and high molecular polymer. It has no pollution and no harmful substances, and is environmentally friendly and efficient.

4.Automation : to achieve industrial 4.0 automation factory, new plant planning preferred solution ! At the same time, it saves labor costs.

It not only replaces kraft paper and silicone pad, but also reduces costs, while realizing the automation requirements of Industry 4.0, and is environmentally friendly and pollution-free !

--We develop the purpose of the Navis pad

Usage :

Product scope : CCL, PCB, FPC, hard and soft bonding board, ICS carrier board, HDI and high frequency high speed circuit board, aluminum substrate, ceramic substrate, new energy, etc.

Henan Huanyuchang Electronic Technology Co.,Ltd., a subsidiary of Shenzhen Chang Universal Electronics Co., Ltd., was founded in 2009 with a strong focus on technological innovation. Specializing in the production of pressing materials such as PCB,FPC,CCL,IC carrier boards, and new energy products, the company has evolved into a prominent enterprise that integrates technological research and development, production, marketing, and technical services. In 2020, the company acquired over 110 acres of state-owned land, leading to a total construction area of 78,000 square meters.

The company's key products include NAWES MATT™ press pads, Japanese metallurgical pressing steel plates, Swedish Hardox carrier plates, and hot-pressed kraft paper. Aligned with the advancements in the 5G industry, efforts have been directed towards achieving energy conservation and emission reduction in line with the requirements of Industry 4.0 for intelligent automation production. With a wide array of equipment over 100 sets, including high-frequency high-speed coating machines, dipping machines, flat press machines, vulcanizing machines, cutting machines, laser marking machines, and punching machines, the company has the capacity to produce significant quantities of its products annually. The company annual produce 1 million square meters of NAWES MATT™ press pads,100,000 pieces of pressing steel plates, 50,000 carrier plates, and 5 million square meters of hot-pressed kraft paper.

Emphasizing technological innovation, the company has fostered a research and development team known for its innovative spirit and expertise. Through continuous research and development, the company has translated technological

leadership into distinct product advantages. The NAWES MAT™ press pads product, developed independently, boasts over 20 technical patents and is ISO certified, contributing to the progress of lndustry 4.0 in China. Recognized with prestigious awards such as the national "China Good Project" award and "High-tech Enterprise" status, the company has garnered acclaim across multiple high-end industries.

As a leading manufacturer of pressing process supporting products domestically and internationally, Huanyuchang offers comprehensive one-stop services that enhance production quality and reduce costs effectively. Backed by a robust management system, a skilled technical team, and advanced German equipment, the company's products set industry standards and are in high demand both domestically and internationally.

With a commitment to technological innovation and customer satisfaction, Huanyuchang aims to deliver high-quality, efficient, and professional services globally through a well-established sales and service network. Positioned strategically for global expansion, the company is poised to continue its trajectory of growth and innovation, aspiring to become a premier global supplier of electronic materials and processes while contributing to the advancement of Chinese brands.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More