In modern industrial manufacturing and processing, lamination cushioning consumables play an indispensable role. As a professional lamination cushioning consumables manufacturer, we are committed to providing reliable lamination cushioning materials and solutions for clients across various industries, helping to enhance production efficiency and product quality.

Application Areas of Lamination Cushioning Consumables

Lamination cushioning consumables are widely used in many fields, including electronic circuit board manufacturing, composite material molding, precision instrument assembly, and automotive interior processing. These materials act as pressure cushions, distribute heat evenly, and protect product surfaces during the lamination process, ensuring the stability of production and the integrity of the final product.

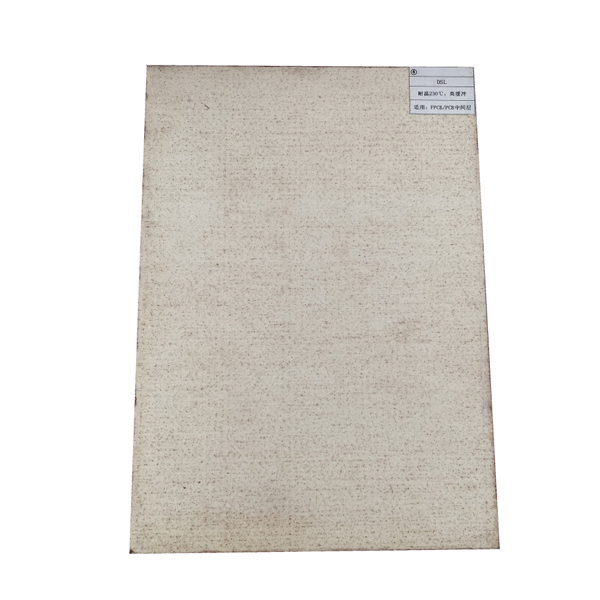

Performance requirements for lamination cushioning materials vary across different application scenarios. For instance, in high-temperature lamination environments, materials need to possess excellent heat resistance and stability, while in precision electronic product manufacturing, low impurity and contamination-free characteristics are essential. As a professional manufacturer, we have an in-depth understanding of the production characteristics of different industries, enabling us to provide targeted solutions for our clients.

Our Product Features

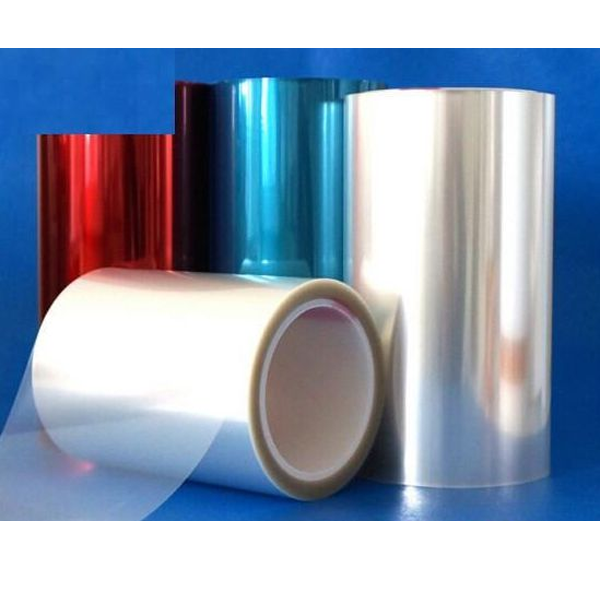

As a manufacturer specializing in the R&D and production of lamination cushioning consumables, we offer a rich and diverse product series to meet the specific needs of different clients:

Diverse Material Options: We provide lamination cushioning materials in various materials, including silicone, rubber, and composite materials. Each material undergoes strict testing to ensure stable performance.

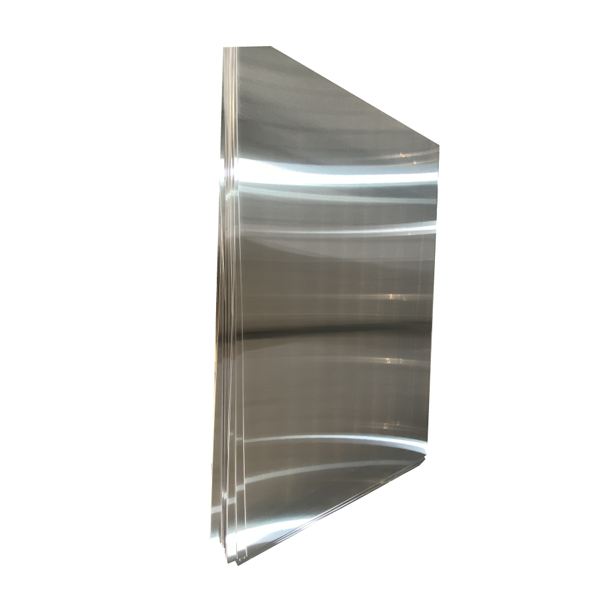

Excellent Thermal Conductivity: Our materials offer superior thermal conductivity, enabling even heat distribution during lamination and preventing issues like localized overheating or uneven heat transfer.

Stable Physical Properties: Our products maintain dimensional stability in high-temperature and high-pressure environments, resisting deformation to ensure consistency in every lamination cycle.

Customizable Designs: We can provide customized dimensions, thicknesses, and shapes based on specific client requirements, ensuring a perfect match with production equipment.

Our Professional Technical Support

As a professional manufacturer, we not only supply high-quality products but also place great emphasis on providing comprehensive technical support to our clients:

Application Consultation: Our technical team can help clients analyze their lamination cushioning needs within the production process and recommend the most suitable material solutions.

Usage Guidance: We provide detailed instructions and operational advice to help clients use lamination cushioning materials correctly, extending their service life.

Problem-Solving: Should any issues arise during use, our technical support team responds promptly to assist clients in finding effective solutions.

Quality Assurance and Continuous Improvement

We understand that quality is the lifeline of an enterprise. Therefore, we have established a strict quality control system covering every stage, from raw material procurement to manufacturing and finished product inspection. We regularly conduct performance tests on our products to ensure every batch meets standard requirements.

Simultaneously, we closely monitor industry developments and technological advancements, continuously optimizing product formulations and production processes. Through close collaboration with clients and gathering usage feedback, we persistently improve product performance to better adapt to the ever-changing market demands.

Environmental Protection and Sustainable Development

In today's society, which places great emphasis on environmental protection, we actively practice the concept of green manufacturing. We are committed to developing eco-friendly lamination cushioning materials, reducing energy consumption and waste generation during production. Furthermore, we are exploring solutions for recyclable lamination cushioning materials, contributing to the sustainable development of the industry.

As a professional manufacturer, we always adhere to a client-centered approach, with quality as our foundation and innovation as our driving force. Regardless of your industry, if you have needs for lamination cushioning materials, we are dedicated to serving you and providing professional, reliable solutions.

Welcome to visit our website for more information, or contact our professional team directly to discuss your specific requirements. We look forward to collaborating with you to jointly advance the level of manufacturing.