In the Printed Circuit Board (PCB) manufacturing process, the lamination stage is one of the critical steps that determines the final product's quality. As a professional manufacturer of PCB lamination cushion pads, we are dedicated to providing stable and reliable lamination cushioning materials for the circuit board industry, helping companies enhance production efficiency and product quality.

Function and Importance of Cushion Pads in PCB Lamination

PCB lamination cushion pads play a vital role in the multilayer circuit board lamination process. These specialized materials are placed between the press platens and the circuit board, effectively distributing pressure evenly, transferring heat, and protecting delicate circuit layers from damage. Suitable lamination cushion pads can significantly reduce issues like uneven pressure and temperature fluctuations during pressing, thereby lowering the incidence of defects such as warpage and delamination in circuit boards.

As electronic devices evolve towards thinner, lighter, and higher-performance designs, PCBs are incorporating more layers and finer circuitry. This trend places higher demands on the lamination process. As a professional PCB lamination cushion pad manufacturer, we deeply understand this trend and continuously optimize our product performance to meet increasingly stringent production requirements.

Characteristics of Our PCB Lamination Cushion Pads

Our PCB lamination cushion pads are specifically designed and rigorously tested, featuring the following properties:

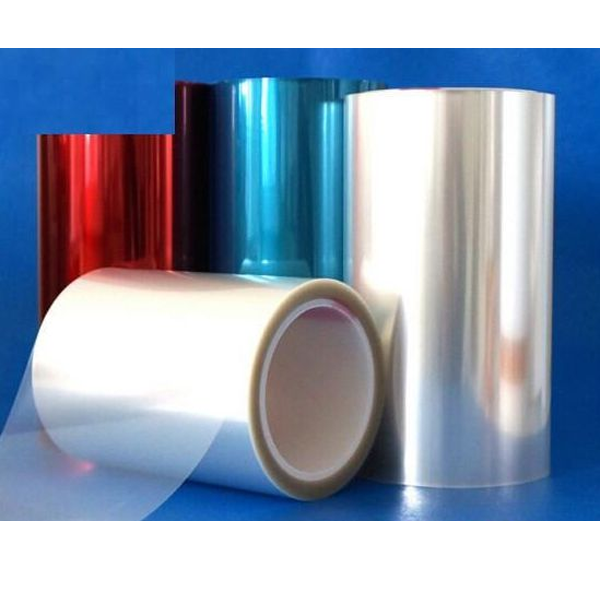

Material Diversity: We offer PCB lamination cushion pads in various materials, including silicone-based and composite types, suitable for different lamination equipment and process conditions. Each material is strictly selected to ensure its chemical and thermal stability meets PCB production requirements.

Uniform Thermal Conductivity: Our cushion pads exhibit excellent thermal conductivity, enabling uniform heat distribution during lamination to prevent circuit board quality issues caused by localized overheating. This characteristic is particularly crucial for manufacturing high-frequency and high-speed PCBs.

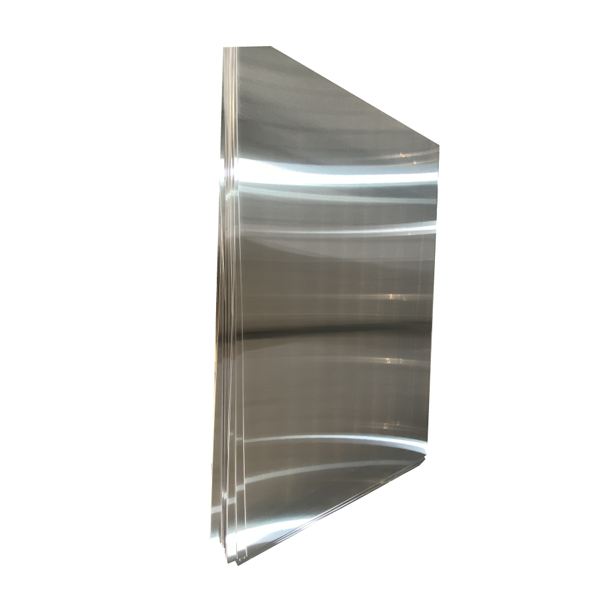

Pressure Distribution: The elastic modulus and compressibility of our products are meticulously engineered to effectively disperse pressure during lamination, minimizing pressure concentration and protecting intricate circuit structures from damage.

Dimensional Stability: In the high-temperature, high-pressure lamination environment, our cushion pads maintain excellent dimensional stability, resisting deformation or shrinkage, ensuring consistent performance even after multiple uses.

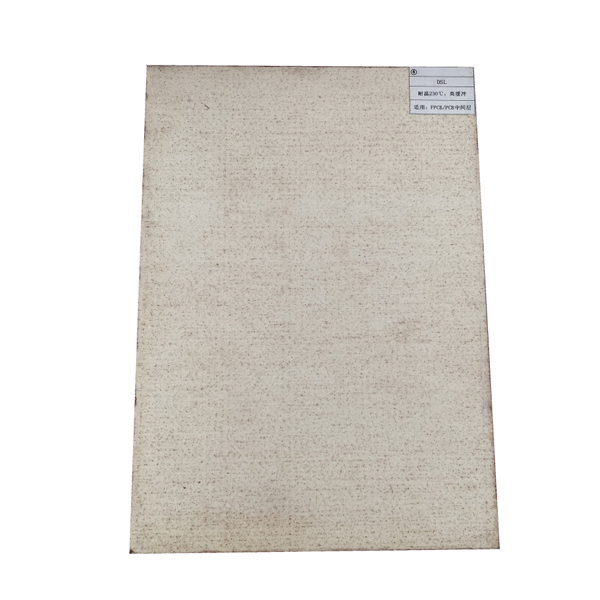

Cleanliness Control: We place special emphasis on product cleanliness control, minimizing particulates and impurities to prevent their transfer onto the circuit board during lamination, which could affect the final product's electrical performance and reliability.

Solutions for Different PCB Types

Understanding that different types of circuit boards have varying requirements for the lamination process, we provide targeted solutions:

Lamination Cushion Pads for Rigid PCBs: Suitable for traditional rigid boards like FR-4, featuring good heat resistance and resilience, ideal for multiple reuses.

Specialized Cushion Pads for High-Frequency PCBs: Addressing the specific needs of high-frequency microwave PCBs, using materials with low dielectric loss to minimize impact on circuit performance.

Lamination Materials for Flexible PCBs: Providing specialized lamination cushioning solutions for FPCs (Flexible Printed Circuits), featuring softer properties and appropriate thermal conductivity.

Auxiliary Materials for High-Layer Count Board Lamination: Offering professional products with excellent stability and pressure distribution for laminating high-layer count PCBs (12 layers and above).

Professional Technical Support and Service

As a manufacturer focused on the PCB field, we provide comprehensive technical support:

Process Consultation: Our experienced technical team can offer optimization advice for lamination process parameters, helping clients select the most suitable cushion pad type and specification.

Application Guidance: We provide detailed product usage instructions and operational recommendations, including installation methods, suggested usage cycles, and maintenance practices, helping clients maximize product value.

Problem Analysis: If clients encounter lamination-related issues during production, our technical support team can help analyze the causes and propose improvement suggestions.

Quality Assurance System

We have established a complete quality assurance system. From raw material procurement to manufacturing and final inspection, each stage adheres to strict control standards. We regularly conduct comprehensive performance tests on our products, including thermal stability, pressure distribution, and durability tests, ensuring every batch meets specified technical indicators.

Furthermore, we maintain long-term cooperative relationships with numerous circuit board manufacturers, continuously gathering usage feedback to improve product performance. We stay abreast of industry technology trends and actively participate in relevant technical exchanges, ensuring our products can meet the evolving needs of PCB manufacturing technology.

As a professional PCB lamination cushion pad manufacturer, we are consistently committed to enhancing the quality of circuit board manufacturing. Through continuous innovation and product optimization, we provide reliable lamination cushioning solutions for our clients. Whether you are a new entrant to the circuit board manufacturing industry or an experienced professional manufacturer, we are here to offer you professional products and technical support.

We cordially invite you to learn more about our product range and discuss your specific needs with our technical team. Let's work together to advance PCB manufacturing technology and development, providing a solid foundation for innovation in the electronics industry.