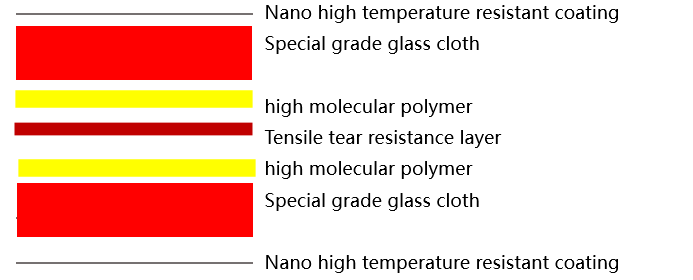

In order to adapt to the new 5G materials and high-standard lamination conditions in the electronics industry, and to follow the environmental protection trend in the industry, our R & D personnel have launched a reusable 260 ° C high-temperature buffer material-Navies mat after years of research and innovation. This product is composed of special grade glass fiber cloth and high molecular polymer. Compared with kraft paper, it is simple to operate, more resistant to high temperature, more stable, more environmentally friendly, more energy-saving, and can be recycled for many times.

Performance Category | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Red hard pad Suitable for CCL | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 500-800 |

| kraft paper | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

This product is the best product to replace kraft paper at present. It is mainly used in CCL pressing process, which can improve the stability of ruler ( industry standard : positive and negative 300ppm, using cushion can reach positive and negative 250ppm ), plate thickness uniformity, stable temperature rise rate and reduce energy consumption.

Independent Research and Development

1.Our in-house R&D team leverages cutting-edge technologies and material science expertise to develop products specifically designed to address the unique challenges of industries like CCL, PCB, and lithium battery manufacturing.

2.Advanced testing and simulation tools enable quick iteration and refinement, ensuring products meet the highest standards of performance, durability, and thermal stability.

3.Ability to modify thickness, thermal conductivity, and compression properties to suit specific customer needs, such as ultra-thin pads for precision applications or high-pressure-resistant variants for heavy-duty processes.

Independent Production

1.Full ownership of the manufacturing process—from raw material sourcing to final product assembly—ensures consistent quality and eliminates reliance on third-party suppliers.

2.Equipped with advanced automation and precision engineering tools, our production lines deliver products with micron-level accuracy and uniformity.

3. Rigorous testing at every stage of production guarantees that each product meets or exceeds industry standards for thermal resistance, compression stability, and durability.

Short Production Cycle

1. Optimized workflows and lean production techniques reduce lead times by 30% compared to industry averages, ensuring faster delivery without compromising quality.

2.Flexible production capacity allows us to handle both small custom orders and large-scale bulk requests efficiently, meeting the demands of diverse industries.

3. Streamlined logistics and inventory management ensure timely delivery, minimizing downtime for customers and keeping production schedules on track.

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

| Compare Item 1 | Navies pad | kraft paper | Compare Item 2 | Navies pad | kraft paper |

| Chi An | ◎ | ◯ | Holding Effect | ◎ | ◯ |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

• No Middle-Markup: Vertical integration from research to manufacturing ensures competitive pricing without compromising quality.

• Agile Innovation: Rapid prototyping and iterative improvements keep the product at the forefront of industry needs, future-proofing your investment.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More