During the printed circuit board (PCB) manufacturing process, every detail determines the quality and performance of the final product. Among them, the lamination process is one of the important links in PCB production, and it is particularly critical for the selection of board materials. As a professional supplier of laminated mirror steel plates, we understand the necessity of high-quality raw materials to achieve efficient and precise production. This article will explore the application and advantages of laminated mirror steel sheets in PCB manufacturing.

[Overview of laminated mirror steel plate]

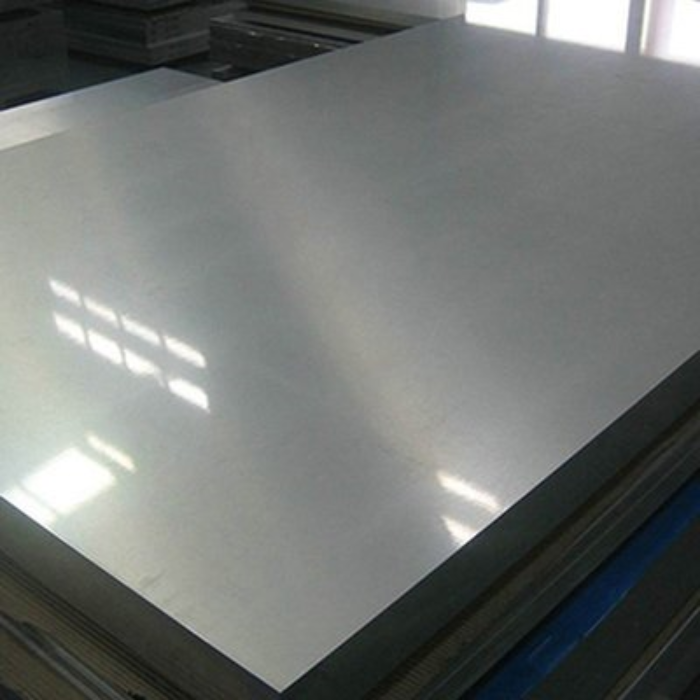

Laminated mirror steel plate is a high-strength steel plate specially used in PCB lamination process. Known for its smooth and flat surface, excellent thermal stability and high strength, it is ideal for efficient PCB lamination. These steel plates are finely processed to ensure their surface finish and dimensional accuracy, thereby meeting the strict flatness and parallelism requirements of PCB production.

[Importance in PCB lamination process]

In the PCB lamination process, laminated mirror steel plates play a vital role:

Uniform Pressure Distribution: The flatness and hardness of the laminated mirror steel plate ensures even pressure distribution throughout the lamination process, which helps eliminate inter-layer gaps and improves PCB reliability and durability.

Temperature control: Since the temperature needs to be precisely controlled during the lamination process, the high thermal conductivity and thermal stability of the laminated mirror steel plate enable it to maintain unchanged performance in high-temperature environments, thus ensuring the consistency of lamination.

Surface finish: The smooth surface reduces scratches or other surface defects that may occur when in contact with the PCB, further improving the quality of the PCB.

[Choose the appropriate laminated mirror steel plate]

To ensure optimal lamination results, it is crucial to select the appropriate laminated mirror steel plate

Material and hardness: The material of the steel plate directly affects its durability and service life. Choosing high-hardness steel can reduce wear and extend service life.

Surface treatment: Fine surface treatment technology is the key to ensuring the surface finish of the steel plate. Mirror-level polishing minimizes defects in PCB production.

Dimensional Accuracy: Precise dimensional control is critical to achieving high-precision lamination. Choosing steel plates with good dimensional stability can avoid deviations during lamination.

【Our advantages】

As a leading manufacturer of laminated mirror steel plates, we not only provide high-standard products, but are also committed to technological innovation and service optimization. Our professional team can provide customized solutions according to customer needs, from product design to after-sales service, to fully support customers' business development.

If you are looking for a reliable laminated mirror steel plate supplier, please feel free to contact us. We look forward to working with you to jointly promote the progress and development of PCB manufacturing industry