With the development of science and technology, electronic products are becoming increasingly miniaturized and diversified in functions, which not only puts higher requirements on the design of printed circuit boards (PCBs), but also brings new challenges to every link in its manufacturing process. In the PCB manufacturing process, lamination is a crucial process that directly affects the quality and performance of the final product. In this context, the importance of PCB lamination carrier as an important tool for supporting and protecting circuit boards cannot be ignored.

Overview of lamination process

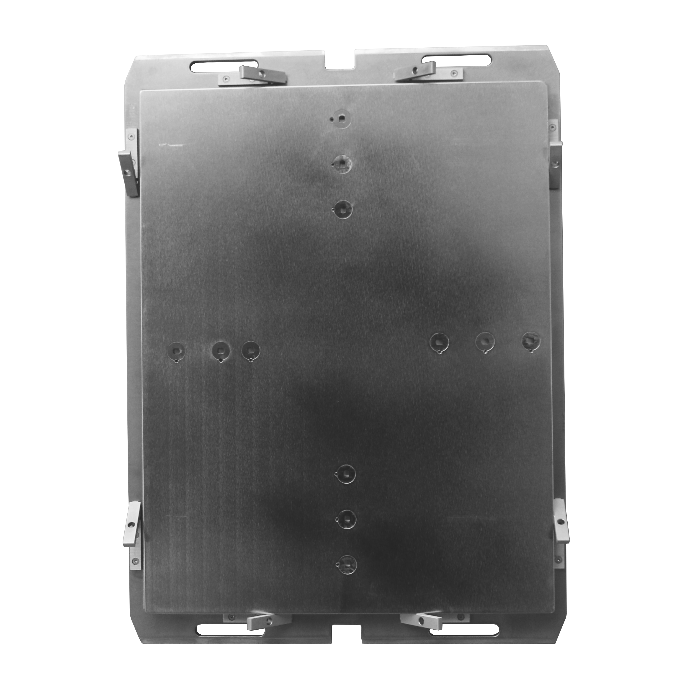

PCB lamination refers to the process of bonding multi-layer circuit boards together by heating and pressurizing. This process is designed to create a complex circuit board structure with functions such as multi-layer routing and hole connection. In order to ensure the quality of lamination, a specially designed carrier tool, namely a lamination carrier, must be used to ensure that the circuit board can still maintain correct alignment and close contact under high pressure and high temperature conditions.

The role of PCB lamination carrier

Precise alignment: When multi-layer circuit boards are stacked, the lamination carrier can help achieve precise alignment between layers to avoid short circuits or other defects caused by misalignment.

Uniform pressure: The carrier plate can ensure uniform pressure distribution over the entire lamination area to prevent local excessive force from causing deformation of the board or interlayer peeling.

Protecting the circuit board: In a high-pressure and high-temperature environment, the carrier plate can also play a certain heat insulation effect to prevent overheating from damaging the components or coating on the surface of the circuit board.

Improve efficiency: Using a dedicated carrier plate can simplify the operation process and speed up production, thereby improving the efficiency of the overall production line.

Material selection of the carrier plate

Depending on different production process requirements, there are also many choices for the material of the lamination carrier plate. Common materials include but are not limited to metal alloys, special engineering plastics and composite materials. The selection of these materials is based on their respective heat resistance, pressure resistance and thermal conductivity.

Metal alloys: Usually used in situations requiring extremely high heat resistance and firmness, such as applications exposed to high temperature environments for a long time in large-scale production.

Special engineering plastics: Suitable for use under medium and low temperature conditions, light weight, relatively low cost, and easy to process and shape.

Composite materials: Combining the advantages of metal and plastic, with both certain rigidity and good thermal insulation performance, it is one of the more popular solutions at present.

Conclusion

As the demand for high-quality PCBs in the electronic product market grows, the importance of press-fit carriers as basic equipment to ensure smooth production is becoming increasingly prominent. By rationally selecting materials and optimizing design structures, not only can product quality be effectively improved, but costs can also be further reduced and production efficiency improved.