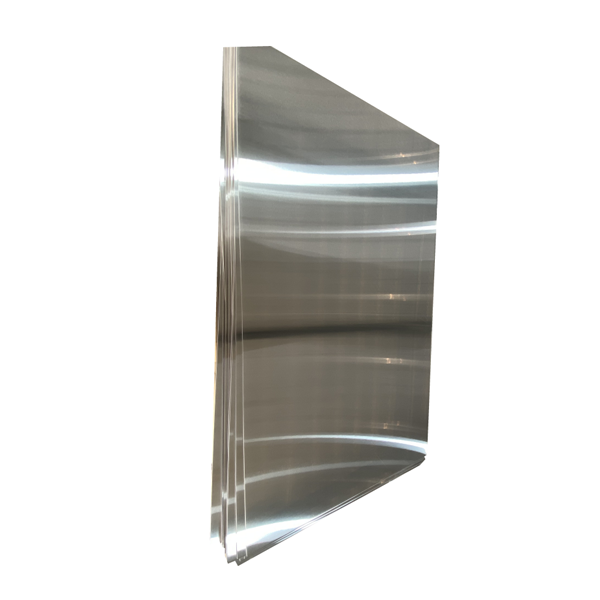

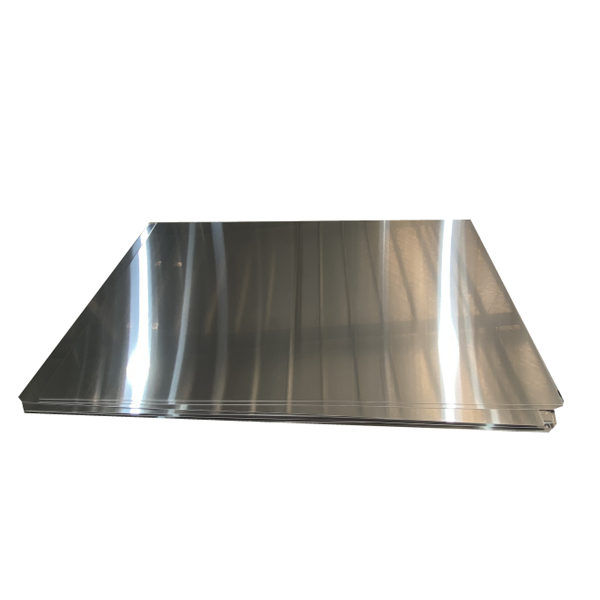

This product uses Sweden 's Hardox450 steel grade for deep processing by our technicians according to customer needs. The carrier plate provided by our company can meet all the pressing production needs of the existing PCB, CCL, FPC, FCCL, IC carrier plate, aluminum substrate and new energy industry.

Product characteristics

| Sweden Hardox450 | |

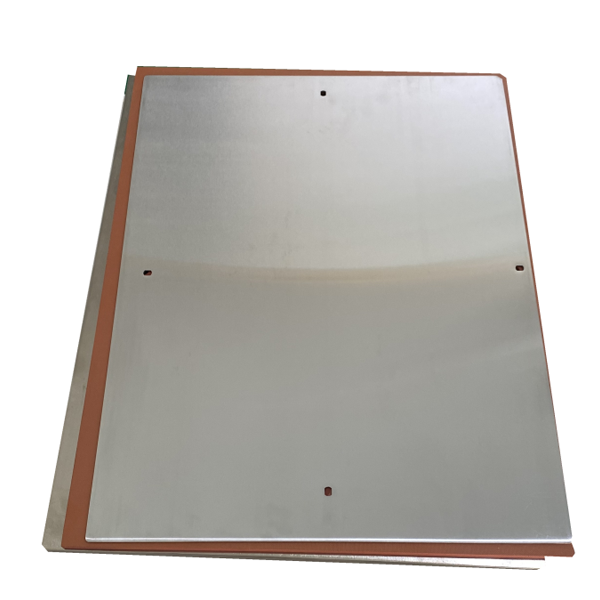

Mass Lanination | Pin Lanination | |

Thickness | 3mm-16mm | 3mm-16mm |

Length | ≦6000mm | ≦6000mm |

Width | ≦1300mm | ≦1300mm |

Dimension tolerances | ±1mm | ±1mm |

Coefficient of thermal expansion | (10~12)*10-6/℃ | (10~12)*10-6/℃ |

Hardness ( HV ) | ≧440 | ≧440 |

Thickness tolerance | ±0.1mm | ±0.1mm |

Working temperature | ≦450℃ | ≦450℃ |

Flatness | ≦2mm/m | ≦2mm/m |

Roughness | Ra≦0.75μm | Ra≦0.75μm |

Positioning hole-to-hole tolerances | / | -0/+0.05mm |

Thermal conductivity W / ( m * k ) | 34(100℃-200℃) 38(200℃-400℃) | 34(100℃-200℃) 38(200℃-400℃) |

Summary :

1.It can work at high temperature of 0 ~ 450 °C, non-carbonization, non-brittleness and stable expansion coefficient ;

2.High hardness, high flatness, high precision parameters in the industry ;

3.Free customization to reduce costs ;

4. Long service life

for PCB, CCL, FPC, FCCL, IC carrier board, aluminum substrate and new energy pressing production needs

Our carrier plate is specifically engineered to meet the rigorous and diverse pressing production needs of a wide range of industries, including PCB (Printed Circuit Board), CCL (Copper Clad Laminate), FPC (Flexible Printed Circuit), FCCL (Flexible Copper Clad Laminate), IC (Integrated Circuit) carrier board, aluminum substrate, and new energy applications. Below, we expand on how our product addresses the unique challenges and requirements of each industry:

1. PCB (Printed Circuit Board) Industry

The production of PCBs demands precision, consistency, and reliability. Our carrier plate, made from Sweden’s premium Hardox450 steel grade, ensures high flatness and dimensional stability, which are critical for achieving uniform pressure distribution during the pressing process. This results in flawless lamination and bonding of multi-layer PCBs, minimizing defects such as delamination or warping. Additionally, its ability to withstand high temperatures (up to 450°C) ensures consistent performance in high-heat environments, making it ideal for the PCB manufacturing process.

2. CCL (Copper Clad Laminate) Industry

Copper Clad Laminates require precise thermal and mechanical control during production. Our carrier plate’s stable expansion coefficient prevents warping or deformation under high temperatures, ensuring the even distribution of heat and pressure. This is essential for producing high-quality CCLs with excellent electrical insulation and mechanical strength. The high hardness of Hardox450 steel also ensures long-term durability, reducing the need for frequent replacements and lowering production costs.

3. FPC (Flexible Printed Circuit) Industry

Flexible circuits require a carrier plate that can handle delicate materials without compromising precision. Our product’s high flatness and precision parameters ensure that the pressing process maintains the integrity of thin and flexible substrates. The non-brittle and non-carbonizing properties of Hardox450 steel make it suitable for the high-temperature environments often used in FPC production, ensuring consistent quality and performance.

4. FCCL (Flexible Copper Clad Laminate) Industry

FCCL manufacturing involves bonding thin layers of copper to flexible substrates, which requires a carrier plate with exceptional thermal stability and surface finish. Our carrier plate’s stable expansion coefficient and high-temperature resistance ensure uniform pressure and heat distribution, preventing defects such as bubbles or uneven bonding. Its long service life and resistance to wear make it a cost-effective solution for high-volume FCCL production.

5. IC (Integrated Circuit) Carrier Board Industry

IC carrier boards are used in advanced electronics and require extreme precision during production. Our carrier plate’s high precision parameters and exceptional flatness ensure that the pressing process meets the tight tolerances required for IC manufacturing. The high hardness of Hardox450 steel ensures durability, even under the demanding conditions of IC production, while its customizable design allows it to be tailored to specific production needs, reducing costs and improving efficiency.

6. Aluminum Substrate Industry

Aluminum substrates are widely used in LED and power electronics due to their excellent thermal conductivity. Our carrier plate’s high-temperature resistance and stable expansion coefficient ensure that the pressing process maintains the structural integrity of aluminum substrates, even under high heat. The high flatness of our product ensures uniform pressure distribution, resulting in high-quality substrates with consistent thermal and electrical performance.

7. New Energy Industry

The new energy sector, including solar panels, batteries, and other renewable energy technologies, demands materials that can withstand extreme conditions. Our carrier plate’s ability to operate at temperatures up to 450°C without carbonization or brittleness makes it ideal for the high-heat environments often encountered in new energy production. Its long service life and high durability ensure reliable performance, even in the most demanding applications, while its customizable design allows it to be adapted to the unique requirements of new energy manufacturing processes.

High-Temperature Performance: Operates reliably at 0°C to 450°C without carbonization or brittleness.

Exceptional Flatness and Precision: Ensures uniform pressure distribution and high-quality output.

Customizable Design: Tailored to meet specific production needs, reducing costs and improving efficiency.

Long Service Life: Resists wear, corrosion, and fatigue, ensuring durability and cost-effectiveness.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More