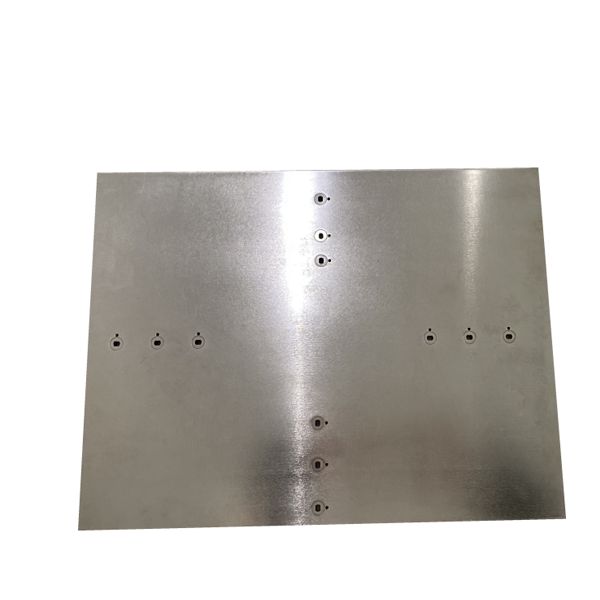

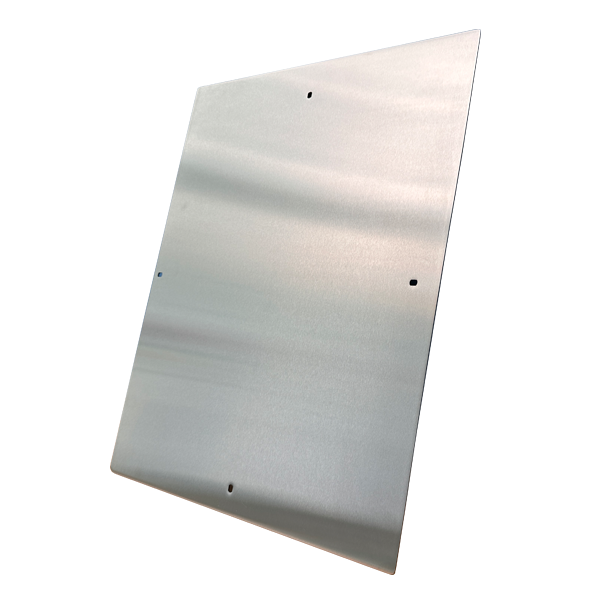

This product uses Sweden 's Hardox450 steel grade for deep processing by our technicians according to customer needs. The carrier plate provided by our company can meet all the pressing production needs of the existing PCB, CCL, FPC, FCCL, IC carrier plate, aluminum substrate and new energy industries.

Material Source & Processing Technology

1. Utilizes Sweden’s SSAB-produced Hardox 450 wear-resistant steel, a globally renowned high-strength, abrasion-resistant steel grade with exceptional mechanical properties and impact resistance.

2. Deep-processed (e.g., cutting, heat treatment, surface finishing) by technical experts to meet customer-specific requirements, ensuring compatibility with diverse industrial applications.

Extreme Environment Adaptability

3.Operates stably in 0–450°C environments without carbonization, embrittlement, or unstable thermal expansion, maintaining dimensional accuracy during high-temperature lamination processes.

4. Superior hardness, flatness, and precision parameters exceed industry standards, ideal for high-accuracy manufacturing.

Flexible Customization

5. Thickness range 3–16mm, with adjustable width and length to match equipment specifications.

6. Tailored production minimizes material waste, reducing procurement and processing costs.

7. Combines Hardox 450’s durability with advanced processing to significantly prolong service life, lowering replacement frequency and downtime costs.

Product characteristics

| Sweden Hardox450 | |

Mass Lanination | Pin Lanination | |

Thickness | 3mm-16mm | 3mm-16mm |

Length | ≦6000mm | ≦6000mm |

Width | ≦1300mm | ≦1300mm |

Dimension tolerances | ±1mm | ±1mm |

Coefficient of thermal expansion | (10~12)*10-6/℃ | (10~12)*10-6/℃ |

Hardness ( HV ) | ≧440 | ≧440 |

Thickness tolerance | ±0.1mm | ±0.1mm |

Working temperature | ≦450℃ | ≦450℃ |

Flatness | ≦2mm/m | ≦2mm/m |

Roughness | Ra≦0.75μm | Ra≦0.75μm |

Positioning hole-to-hole tolerances | / | -0/+0.05mm |

Thermal conductivity W / ( m * k ) | 34(100℃-200℃) 38(200℃-400℃) | 34(100℃-200℃) 38(200℃-400℃) |

Summary :

1.It can work at high temperature of 0 ~ 450 °C, non-carbonization, non-brittleness and stable expansion coefficient ;

2.High hardness, high flatness, high precision parameters in the industry ;

3.Free customization to reduce costs ;

4. Long service life

for PCB, CCL, FPC, FCCL, IC carrier board, aluminum substrate and new energy pressing production needs

Electronics Manufacturing

PCB (Printed Circuit Board): Multi-layer board lamination, copper-clad laminate (CCL) pressing.

FPC/FCCL (Flexible Printed Circuit/Flexible Copper Clad Laminate): Precision thermal pressing for flexible materials.

IC Carrier Boards: High-precision substrates for semiconductor packaging

New Energy & Thermal Management

Aluminum Substrates: LED heat sinks, power module lamination.

Battery Production: Thermal pressing for battery modules, separator material processing.

Customized pricing according to customers

Note : Product attributes : production thickness 3 ~ 16mm, width, length, can be customized to meet customer needs

( according to the applicable product specifications, and customer requirements, matching the corresponding thickness ; our products are produced by order. )

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More