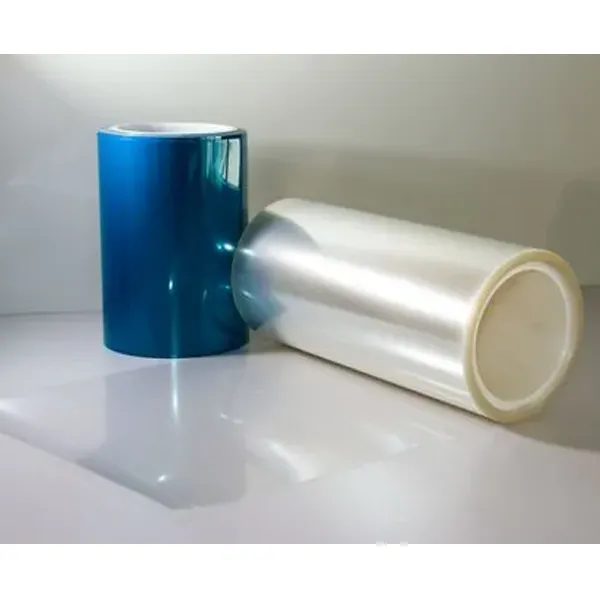

In PCB (printed circuit board) and composite material lamination processes, release film plays an indispensable role as a "guardian." It sits between the product and the buffer pad, ensuring perfect demolding while protecting expensive mirror steel plates and lamination buffer pads from contamination. When standard release film can no longer meet your increasingly refined process requirements, "custom release film" becomes an inevitable choice. However, upon hearing the word "custom," many purchasing decision-makers immediately associate it with "costly." As a comprehensive solution provider deeply rooted in the field of lamination materials, we aim to break this misconception. This article will thoroughly analyze the various factors influencing the price of custom release film and explain why, from the perspective of total cost of ownership (TCO), custom-designed release film is often the most economical choice for achieving optimal production efficiency and exceptional quality.

I. Deconstructing the Price Composition: The "Value" Code of Customized Release Liner

The price of custom release film is not a single number, but a comprehensive reflection determined by multiple technical factors. Understanding its components is the first step to making an informed decision.

1. Core substrate cost: The foundation of performance

Material selection: This is the basis for determining the price. Common options include:

PET (polyethylene terephthalate): Economical and widely used, with limited heat resistance.

PEN (Polyethylene naphthalate) : Superior heat resistance and dimensional stability compared to PET, with moderate price.

PI (Polyimide) : Excellent high-temperature resistance (long-term above 260℃), high price, suitable for demanding scenarios such as high-end packaging and high-frequency high-speed boards.

TPX (Poly(pentene-1)) : Outstanding chemical inertness and release properties, suitable for special resin systems.

The cost difference of raw materials from different materials can be several times or even tens of times.Thickness and Specifications: The thickness of the base material (ranging from 25μm to 125μm), width, and roll length directly affect the amount of raw material used per roll and the price. Thicker films usually have better mechanical strength, but they are also more expensive.

2. Release Agent and Coating Technology: The Soul of Functionality

Release Force Precision Control: This is the core of customization. According to the customer's process (such as high or low adhesion pre-impregnated sheets), we need to adjust the release agent formula to achieve precise control of "light release force," "medium release force," or "heavy release force." Too high a release force may lead to difficulty in pressing the plate or deformation of the board; too low may cause slippage during lamination. The technical development and production costs for such specific release forces will be reflected in the price.

Functional Coatings: To meet special requirements, coatings may be endowed with more functions:

Heat Resistance: Ensures no residue remains and no aging occurs during multiple lamination processes or high-temperature operations.

Anti-static Properties: Prevents dust adhesion and protects the cleanliness of products in cleanroom environments.

Silicone Oil-Free Formula: Avoids silicone oil transfer contamination, which is crucial for certain electronic applications.

Each additional functional requirement means an increase in formula complexity and production difficulty.

3. Customized Production Processes and Control: The Cost of Precision

Coating Process: High-precision quantitative coating technology is key to ensuring uniform adhesion force. Advanced slot die coating or microgravure coating equipment can achieve extreme uniformity compared to conventional coating methods, but they also come with higher equipment investment and operational costs.

Cleanroom Environment: For high-end applications, coating and slitting within a dust-free workshop is essential to prevent dust particles from being pressed into the surface, which directly increases the cost of environmental control.

Slitting and Packaging: Slitting according to the exact dimensions provided by the customer (width, length) and using customized packaging that is dust-proof and moisture-proof also contribute to the overall cost.

4. R&D, Testing and Technical Services: Hidden Value

The customization process begins with in-depth technical communication. Our engineers need to understand your pressure cushion pad characteristics, resin system, process parameters and quality pain points in order to propose effective customized solutions. The subsequent cycle of sample making, testing, adjustment, as well as long-term after-sales service and technical support, are all the added values provided by professional manufacturers.

II. Going Beyond Unit Price: Calculating the "Total Cost of Ownership" for Customized Release Films

Just like pressure cushion pads, focusing only on the unit price per square meter of release film is short-sighted. The true cost-effectiveness should be calculated based on its total cost of ownership.

TCO (Total Cost of Ownership) = Purchase unit price + Quality risk cost + Production efficiency cost + System loss cost

Let's have a clear understanding through a comparison table:

| Cost items | General-purpose/cheap release film | Customized release film | Analysis and Impact |

|---|---|---|---|

| Purchase Unit Price | Lower | Higher | When purchasing for the first time, general-purpose release film may appear to have a clear cost advantage. |

| Quality risk cost | Very high | Very low | General-purpose release film may lead to poor release (difficult peeling, residue), transfer contamination (silicone oil, impurities), and laminating defects (pits, white streaks). A single batch of product scrap or customer returns due to release film issues can result in losses far exceeding the total cost of purchasing general-purpose release film. |

| Production efficiency cost | Higher | Lower | Downtime for debugging, frequent replacement, and handling defective panels caused by release film problems significantly reduces the utilization rate of the press and per capita output. Customized release film, with its stable performance, ensures smooth and efficient production processes. |

| System Loss Cost | Higher | Lower | Low-quality release film may crack due to insufficient heat resistance, causing contamination and damage to expensive mirror steel plates and bonding buffer pads, leading to the need for premature cleaning, maintenance, or replacement of these core components and resulting in significant indirect costs. |

Conclusion is clear: A custom release film that perfectly matches your process and eliminates quality risks brings substantial improvements in yield, efficiency, and equipment protection, far outweighing the slight price difference compared to standard products. It is not merely a "cost," but an "investment" that enhances overall competitiveness.

III. Wise Investment: How to Collaborate with Suppliers to Achieve Optimal Custom Cost-Effectiveness?

Achieving high cost-effectiveness through customization hinges on establishing a close partnership with the supplier.

1. Accurately define your requirements:

Before communicating with us, please try to clarify as much as possible:

Your substrate and resin type: Is it FR-4, high-frequency material, or high TG material? What is the resin's adhesion property?

Your lamination process window: maximum lamination temperature, pressure level, and duration.

Your quality pain points: are you mainly facing demolding issues, surface contamination, or marks on the board after lamination?

Your equipment and stacking method: the condition of the steel plate and buffer pad, as well as the stacking method.

2. Trust the technical solutions from professional manufacturers:

As a comprehensive solution provider that simultaneously produces buffer pads, mirror steel plates, carrier plates, and release films, we have a unique system perspective. We can start from the synergy of the entire lamination system and recommend the release film solution that best protects your steel plates and buffer pads while ensuring lamination quality. This system-level matching optimization can bring you unexpected long-term benefits.

3. Conduct rigorous sample testing and evaluation:

"Let the horse show its mettle." We require you to provide customized samples according to your needs and perform small-batch verification on your production line. The evaluation focuses on:

Demolding effect: Is it smooth with no residue?

Sheet Surface Quality: Is the surface smooth, free from contamination and marks after lamination?

Operational Convenience: Is it easy to apply and remove?

Impact on the System: After use, are the steel plates and buffer pads kept clean?

Using test data to verify the value of the customized solution is the most effective way to alleviate price concerns.

Invest in exceptional craftsmanship, not just raw materials

In the pursuit of ultimate quality and stable production, every investment should yield the maximum return. Customized release film is not simply "more expensive," but "more valuable." It shows respect for your unique process, ensures high-quality output, and protects your entire lamination system assets.

We sincerely invite you to step beyond the limitations of "unit price" and reevaluate your release film procurement decisions from the perspective of total cost of ownership and strategic partnership. Let's start with an in-depth process discussion and co-create the most efficient, quality-assuring, and cost-effective release film solution tailored specifically for you. Because our goal is to help you achieve every perfect lamination together.