In the modern manufacturing processes of high-density interconnect (HDI) and multilayer printed circuit boards (PCB), the lamination process is one of the core steps that determine the reliability and performance of the final product. As a key fixture in this process that directly contacts the materials and transmits pressure and heat, the quality of the mirror plate directly affects the success or failure of the lamination outcome. This article will delve into the technical characteristics, core functions, and scientific criteria that should be followed when selecting and maintaining PCB laminating mirror plates.

Precisely Defined Process Role

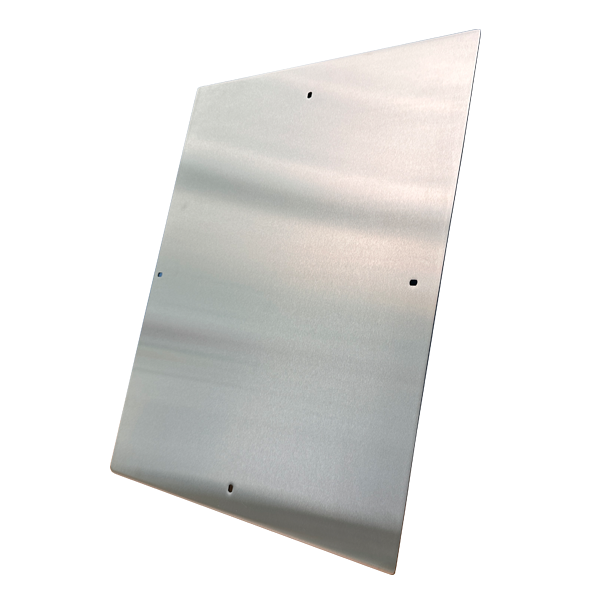

PCB Pressing Mirror Plate, typically made from high-quality alloy tool steel through multiple precise machining and heat treatment processes, is characterized by its extremely high surface flatness, smoothness, and excellent heat and pressure resistance. It is placed above and below the lamination stack (comprising copper foil, pre-preg, inner core board, and buffer pads) in vacuum or non-vacuum laminators. When the laminator closes, under high temperature and pressure conditions, the mirror plate performs multiple critical functions:

Firstly, it evenly transmits pressure and heat. This is its most fundamental function. The high flatness of the mirror surface ensures that pressure is uniformly applied across the entire board area without deviation, preventing issues such as local adhesion failure, insufficient filling, or uneven resin flow. At the same time, its excellent thermal conductivity ensures that the heat from the heating plate is efficiently and evenly transferred to the PCB stack, allowing the resin in the pre-preg to fully melt, flow, and cure, forming a uniform and consistent dielectric layer.

Secondly, it ensures the flatness and appearance of the board surface. The "mirror" level of surface smoothness (usually reaching Ra ≤ 0.4µm or even higher) effectively suppresses and replicates a smooth outer surface of the PCB, preventing copper foil from being indented, pitted, or exhibiting an "orange peel" effect. This provides an ideal base for subsequent fine circuit line processes, such as phototransfer and etching. For PCBs that require high appearance quality or special surface treatments, this is particularly important.

Thirdly, it offers durability and stability. Under severe working conditions involving frequent thermal cycles (usually up to 180°C-220°C) and high pressure (up to hundreds of psi), high-quality mirror plates must maintain extremely low deformation, excellent anti-creep properties, and long-term stable surface characteristics to ensure process consistency in mass production.

Scientific Consideration of Core Performance Indicators

Assessing the professional level of a PCB laminated mirror plate requires attention to the following core dimensions:

Material and Heat Treatment: Typically, special tempered mold steel (such as pre-hardened mold steel) is used to ensure it maintains sufficient hardness and strength at working temperatures. Skilled heat treatment processes are key to eliminating internal stresses and preventing thermal deformation.

Surface Flatness and Smoothness: Flatness usually requires an error of only several micrometers over hundreds of millimeters in length. A highly smooth surface not only enhances the lamination effect but also facilitates cleaning and maintenance, reducing resin residue.

Dimensional Accuracy and Stability: Precise thickness tolerance and excellent thermal dimensional stability form the hardware foundation for ensuring uniform and controllable thickness of the dielectric layer after lamination, meeting the impedance design requirements.

Surface Coating Technology (Optional): Some high-end mirror steel plates will adopt special physical or chemical coatings (such as hard chrome plating, nickel-phosphorus plating, or Teflon coating), to further enhance their wear resistance, corrosion resistance, release performance, and ease of cleaning.

Recommendations for Reasonable Selection and Scientific Maintenance

When facing different supply sources on the market, users need to comprehensively evaluate based on their product types, lamination process parameters (temperature, pressure, vacuum level), and production capacity requirements. Collaborating with suppliers who have a strong metallurgical background, precision processing capabilities, and comprehensive testing methods usually provides more reliable technical support and product quality assurance.

It is worth noting that mirror plate is a high-value precision tooling, and its service life and performance greatly depend on scientific daily maintenance. This includes:

Standardized operation: Avoid mechanical damage caused by hard objects scraping or improper handling.

Thorough cleaning: After each lamination, it is necessary to use dedicated cleaning agents and soft materials to promptly remove resin residue from the surface of the plate, preventing carbon buildup from affecting the surface condition and heat conduction.

Regular inspection and calibration: Periodically use professional instruments to check the flatness and surface condition of the plate. For plates that have already developed micro-deformations or surface damage, contact professional manufacturers for evaluation and repair promptly, rather than continuing to use them.

PCB Pressing Mirror Plate, though not a direct part of the final product, serves as an essential "flatness guardian" in achieving high-quality PCB lamination. In today's era where electronic devices continue to evolve toward miniaturization, high frequency and high speed, and enhanced reliability, a deep understanding of the technical aspects of this key fixture, along with its professional selection, application, and maintenance, has become a crucial step in enhancing the core process capabilities of PCB manufacturers and ensuring product yield and stability. Scientific attention and management toward mirror plates essentially represent a long-term investment in the precision of the overall manufacturing process.