1. Product Features

· The surface of NAS630 steel plate has undergone special treatment, endowing it with good wettability and adhesiveness. During the lamination process, the NAS630 steel plate can form a firm bonding interface with other materials such as metals, ceramics, or plastics, thus improving the overall performance of the laminated structure.

· NAS630 steel plate uses lightweight reinforcing materials such as carbon fiber or aramid fiber. During the lamination process, the NAS630 steel plate can achieve lightweight design, reducing the weight of the final product while maintaining high strength and high rigidity. It is suitable for weight - sensitive application fields like aerospace and automotive.

· Excellent heat resistance: NAS630 steel plate usually contains high - heat - resistant resins such as epoxy resin or polyimide, and reinforcing materials such as glass fiber or carbon fiber. During the lamination process, the NAS630 steel plate can withstand high - temperature environments, and is not prone to deformation or degradation, ensuring the stability and reliability of the laminated structure.

· High mechanical strength: During the lamination process, the NAS630 steel plate can withstand high pressure and shear forces, ensuring that the laminated material has high strength and durability, making it suitable for high - load application scenarios.

· The resin matrix and reinforcing materials of NAS630 steel plate have high fatigue resistance. During the lamination process, the NAS630 steel plate can endure repeated stress cycles, avoiding the failure of the laminated structure due to fatigue and extending the service life of the product.

· NAS630 steel plate adopts environmentally - friendly resins and harmless reinforcing materials. During the lamination process, the NAS630 steel plate reduces environmental pollution, meeting the requirements of modern industry for environmental protection and sustainable development.

Excellent Surface Wettability and Adhesiveness:The surface of the NAS630 steel plate undergoes special treatment, resulting in excellent wettability and adhesiveness. During the lamination process, it forms a strong and durable bonding interface with other materials, such as metals, ceramics, or plastics. This enhances the overall performance of the laminated structure, making it suitable for applications requiring robust material bonding, such as in composite materials and multi-layer structures. The strong bonding capability ensures the structural integrity and longevity of the final product.

Lightweight Design with High Strength:The NAS630 steel plate utilizes lightweight reinforcing materials such as carbon fiber or aramid fiber, enabling a lightweight design without compromising strength or rigidity. During the lamination process, this reduces the overall weight of the final product while maintaining high performance. This makes the NAS630 steel plate ideal for weight-sensitive applications in industries such as aerospace, automotive, and sports equipment manufacturing. The lightweight design also contributes to improved fuel efficiency in automotive and aerospace applications.

Excellent Heat Resistance:The NAS630 steel plate is composed of high-heat-resistant resins, such as epoxy resin or polyimide, combined with reinforcing materials like glass fiber or carbon fiber. This composition allows the NAS630 steel plate to withstand high-temperature environments during the lamination process without deformation or degradation. As a result, it ensures the stability and reliability of the laminated structure, making it ideal for applications in industries such as aerospace, automotive, and electronics where thermal stability is critical.

High Mechanical Strength:The NAS630 steel plate is designed to withstand high pressure and shear forces during the lamination process, ensuring that the laminated material exhibits exceptional strength and durability. This makes it ideal for high-load application scenarios, such as in construction, heavy machinery, and aerospace industries, where materials are subjected to extreme mechanical stress. The high mechanical strength of the NAS630 steel plate ensures the structural integrity of the final product, even under demanding conditions.

High Fatigue Resistance:The resin matrix and reinforcing materials of the NAS630 steel plate exhibit high fatigue resistance, enabling it to withstand repeated stress cycles during the lamination process. This prevents fatigue failure in the laminated structure, extending the service life of the product. This feature is particularly valuable in applications where materials are subjected to continuous mechanical stress, such as in automotive components and industrial machinery.

Environmentally Friendly Materials:The NAS630 steel plate is manufactured using environmentally friendly resins and non-toxic reinforcing materials, reducing environmental pollution during both production and use. This aligns with modern industry requirements for environmental protection and sustainable development. Its eco-friendly composition makes it suitable for applications in green building projects, renewable energy systems, and other industries prioritizing sustainability.

2.Specification

project | NAS630 | |

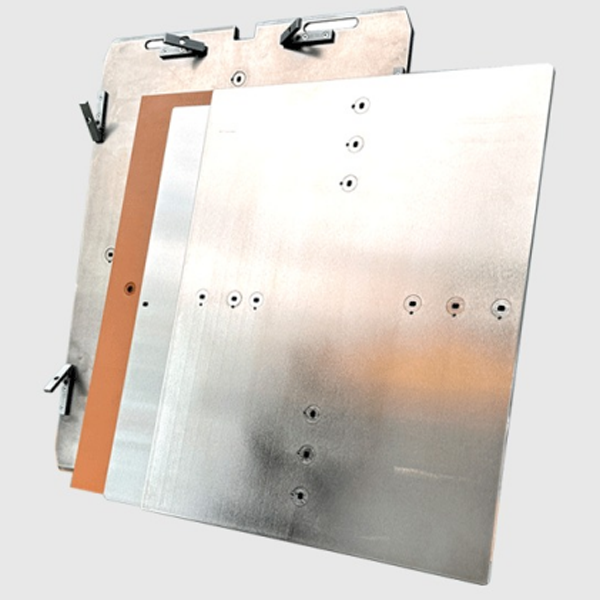

Mass-Lam | Pin-Lam | |

Thickness | 1.0~2.5mm | 1.0~2.5mm |

Width | ≦1300mm | ≦1300mm |

Length | ≦2410mm | ≦2410mm |

Plate thickness tolerance | ±0.05mm | ±0.05mm |

Roughness | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ |

Hole-to-hole tolerances for positioning holes | -- | +0.1/-0mm |

Standard bushing slot hole tolerances | -- | +0.05/-0mm |

Warpage degree | ≦3mm/m | ≦3mm/m |

Dimension tolerances | -0/+1mm | -0/+1mm |

Endurance | ≧1175(N/mm²) | ≧1175(N/mm²) |

Tensile strength | ≧1400(N/mm²) | ≧1400(N/mm²) |

Extensionality | ≧5% | ≧5% |

Hardness ( HRC ) | 50±2 | 50±2 |

3.Chemical Composition(%)

Type | C | Si | Mn | Ni | Cr | Mo | Cu | other |

NAS630 | ≦0.07 | ≦1 | ≦1 | 3~5 | 15~17.5 | - | 3~5 | Nb0.15~0.45 |

4.Physical Property

Steel plate type | Project | Scope of application | Standard value |

NAS630 | specific gravity | - | 8.03 |

mean coefficient of thermal expansion (10-6/℃) | 0-400℃ | 10~12 |

5.Thermal Conductivity

Steel plate type | bench markW/(m*k) | 0-200℃ | 200-400℃ |

NAS630 | 18~23 | 18 | 23 |

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More