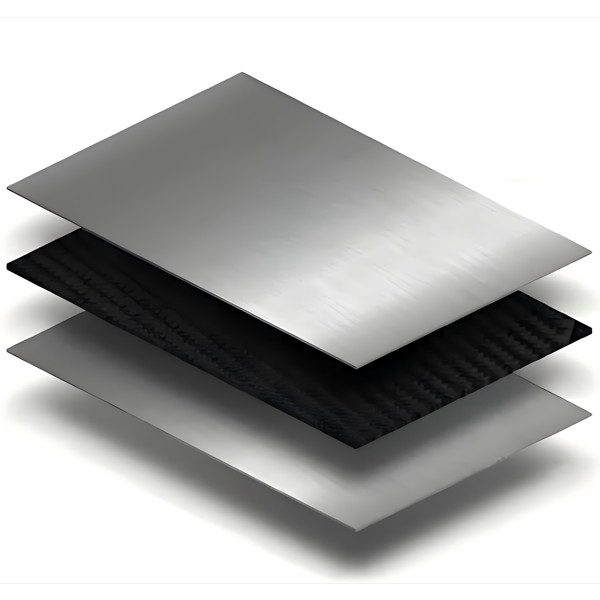

1. Product Features

· Exceptional Wear Resistance: The 4120 laminated steel plate features a high - hardness wear - resistant layer on its surface. During the lamination and usage, it can effectively withstand various mechanical actions like friction and scratching. This reduces material loss and performance degradation caused by wear, extends the service life of laminated products, and is especially suitable for applications with high demands for wear resistance. For instance, printed circuit boards may experience various friction operations during production, and the 4120 steel plate can handle them adeptly.

The 4120 laminated steel[1] plate is equipped with a high-hardness wear-resistant layer on its surface, providing exceptional resistance to friction and scratching during both the lamination process and subsequent use. This significantly reduces material loss and performance degradation caused by wear, extending the service life of laminated products. It is particularly suitable for applications requiring high wear resistance, such as in the production of printed circuit boards (PCBs), where the steel plate can withstand various friction operations during manufacturing without compromising performance. This wear resistance also makes it ideal for heavy machinery and industrial equipment subjected to constant abrasion.

· Stable Supporting Function: As a supporting material, the 4120 laminated steel plate provides stable support for other components within the laminated structure. During lamination, it ensures the accurate relative positions of different layers of materials, facilitating the formation of a uniform and stable laminated structure. In use, it can bear the weight of other components and various stresses, maintaining the overall shape and performance of the laminated product. For example, in printed circuit boards, it offers a reliable support base for numerous electronic components.

As a supporting mater[2] ial in laminated structures, the 4120 laminated steel plate provides reliable support for other components. During the lamination process, it ensures the precise alignment of various material layers, contributing to the formation of a uniform and stable laminated structure. In practical use, it can bear the weight of other components and withstand various stresses, maintaining the overall shape and performance of the laminated product. For instance, in printed circuit boards (PCBs), it offers a stable foundation for numerous electronic components, ensuring the reliable operation of electronic devices in complex environments.

· Optimal Composition Combination: The composition of the 4120 laminated steel plate has been carefully designed and optimized. The interactions among various elements jointly endow the steel plate with good comprehensive properties. For example, it may contain alloy elements in specific proportions. These elements help enhance the steel plate's hardness, toughness, corrosion resistance, etc., enabling the steel plate to better adapt to different process conditions such as high temperature and high pressure during lamination and maintain stable performance in diverse environments.

The compositio[3] n of the 4120 laminated steel plate has been meticulously designed and optimized. The interaction of various alloy elements, such as chromium and nickel, enhances the plate's hardness, toughness, and corrosion resistance. This enables the steel plate to adapt to high-temperature and high-pressure conditions during the lamination process while maintaining stable performance in diverse environments. The optimized composition not only improves the mechanical properties of the steel plate but also extends its service life and reduces maintenance costs. In the chemical industry, its corrosion resistance makes it an ideal choice for handling corrosive media.

· Enhanced Corrosion Resistance: Its composition may include some elements with anti - corrosion properties, such as chromium and nickel. This gives the 4120 laminated steel plate certain corrosion resistance during lamination and usage. It can resist the erosion of moisture, chemicals, etc., in the external environment, preventing the steel plate surface from rusting or corroding. Thus, it avoids adverse effects on the performance of the laminated structure and improves the service life and reliability of laminated products, especially for those used in harsh environments.

The 4120 laminated s[4] teel plate includes corrosion-resistant elements such as chromium and nickel, providing enhanced resistance to moisture and chemical erosion during both the lamination process and use. This prevents the steel plate surface from rusting or corroding, avoiding adverse effects on the performance of the laminated structure and improving the service life and reliability of laminated products. This makes it particularly suitable for laminated products used in harsh environments, such as those exposed to high humidity or corrosive chemicals.

· Good Thermal Stability: From the perspective of composition, the 4120 laminated steel plate has good thermal stability. During the lamination process, if high - temperature processes are involved, it can maintain stable physical and chemical properties, without deforming, softening, or undergoing other adverse changes due to high temperature. This ensures the smooth progress of the lamination process and the quality of the laminated product. In use, when facing a potentially high - temperature environment, it can also maintain its own performance and safeguard the stability of the laminated structure.

From a compositiona[5] l perspective, the 4120 laminated steel plate exhibits excellent thermal stability. During the lamination process, even when exposed to high-temperature conditions, it maintains stable physical and chemical properties without deforming, softening, or undergoing other adverse changes. This ensures the smooth progress of the lamination process and the quality of the final product. In high-temperature usage environments, it continues to perform reliably, ensuring the stability of the laminated structure. Its thermal stability makes it a preferred material in industries such as aerospace, automotive manufacturing, and high-temperature industrial equipment.

project | Germany Outokumpu 4210 | |

Mass-Lam | Pin-Lam | |

Thickness | 0.5~2.0mm | 0.5~2.0mm |

Width | ≦1300mm | ≦1300mm |

Length | ≦2500mm | ≦2500mm |

Plate thickness tolerance | ±0.05mm | ±0.05mm |

Roughness | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ |

Hole-to-hole tolerances for positioning holes | -- | ±0.05mm |

Standard bushing slot hole tolerances | -- | ±0.05mm |

Warpage degree | ≦3mm/m | ≦3mm/m |

Dimension tolerances | -0/+1mm | -0/+1mm |

Endurance | ≧1400(N/mm²) | ≧1400(N/mm²) |

Tensile strength | ≧1500(N/mm²) | ≧1500(N/mm²) |

Extensionality | ≧5% | ≧5% |

Hardness ( HRC ) | 50±2 | 50±2 |

Type | C | N | M | Ni | Cr | P | Other |

Outokumpu 4210 | ≦0.25 | - | ≦2 | - | ≦18 | - | - |

Steel plate type | Project | Scope of application | Standard value |

Outokumpu 4210 | specific gravity | - | 8.03 |

mean coefficient of thermal expansion (10-6/℃) | 0-400℃ | 10~12 |

5.Thermal Conductivity

Steel plate type | bench markW/(m*k) | 0-200℃ | 200-400℃ |

Outokumpu 4210 | 17~21 | 18 | 25 |

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More