Our business scope includes laminated steel plate business, the main agent of Japan 's gold mirror steel plate ( original import ), including NAS630 & NAS301 ( high expansion coefficient ) precipitation hardening steel plate. The product has won the pursuit of CCL / PCB customers with ultra-high hardness, extremely low surface roughness and excellent thermal conductivity. At the same time, the leveling, grinding, polishing, cutting and repairing of the pressed mirror steel plate are merged.

Our business specializes in laminated steel plates, including the exclusive distribution of Japan's high-quality mirror steel plates, such as the NAS630 and NAS301 series. These products are renowned for their high expansion coefficient and precipitation hardening properties. The FCCL Special Pressed High Temperature Resistant Steel Plate is particularly favored by CCL/PCB customers for its superior performance in terms of hardness, surface finish, and thermal management. Additionally, we offer comprehensive services including leveling, grinding, polishing, cutting, and repair of pressed mirror steel plates

project | NAS630 | NAS301 | ||

Mass-Lam | Pin-Lam | Mass-Lam | Pin-Lam | |

Thickness | 1.0~2.5mm | 1.0~2.5mm | 1.0~1.8mm | 1.0~1.8mm |

Width | ≦1300mm | ≦1300mm | ≦1060mm | ≦1060mm |

Length | ≦2410mm | ≦2410mm | ≦3150mm | ≦3150mm |

Plate thickness tolerance | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

Roughness | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ |

Hole-to-hole tolerances for positioning holes | -- | +0.1/-0mm | -- | +0.1/-0mm |

Standard bushing slot hole tolerances | -- | +0.05/-0mm | -- | +0.05/-0mm |

Warpage degree | ≦3mm/m | ≦3mm/m | ≦3mm/m | ≦3mm/m |

Dimension tolerances | -0/+1mm | -0/+1mm | -0/+1mm | -0/+1mm |

Endurance | ≧1175(N/mm²) | ≧1175(N/mm²) | ≧205(N/mm²) | ≧205(N/mm²) |

Tensile strength | ≧1400(N/mm²) | ≧1400(N/mm²) | ≧520(N/mm²) | ≧520(N/mm²) |

Extensionality | ≧5% | ≧5% | ≧40% | ≧40% |

Hardness ( HRC ) | 50±2 | 50±2 | 44±2 | 44±2 |

Type | C | Si | Mn | Ni | Cr | Mo | Cu | other |

NAS630 | ≦0.07 | ≦1 | ≦1 | 3~5 | 15~17.5 | - | 3~5 | Nb0.15~0.45 |

NAS301 | ≦0.15 | ≦1 | ≦2 | 6~8 | 16~18 | - | - | - |

Steel plate type | Project | Scope of application | Standard value |

NAS630 | specific gravity |

| 8.03 |

mean coefficient of thermal expansion (10-6/℃) | 0-400℃ | 10~12 | |

NAS301 | specific gravity |

| 8.03 |

mean coefficient of thermal expansion (10-6/℃) | 0-400℃ | 15~17 |

The product has won the pursuit of CCL / PCB customers with ultra-high hardness, extremely low surface roughness and excellent thermal conductivity.

The FCCL Special Pressed High Temperature Resistant Steel Plate is a premium product designed to meet the demanding requirements of CCL (Copper Clad Laminate) and PCB (Printed Circuit Board) manufacturers. This product stands out due to its ultra-high hardness, extremely low surface roughness, and excellent thermal conductivity, making it an ideal choice for high-performance applications.

Steel plate type | bench markW/(m*k) | 0-200℃ | 200-400℃ |

NAS630 | 18~23 | 18 | 23 |

NAS301 | 17~21 | 17 | 21 |

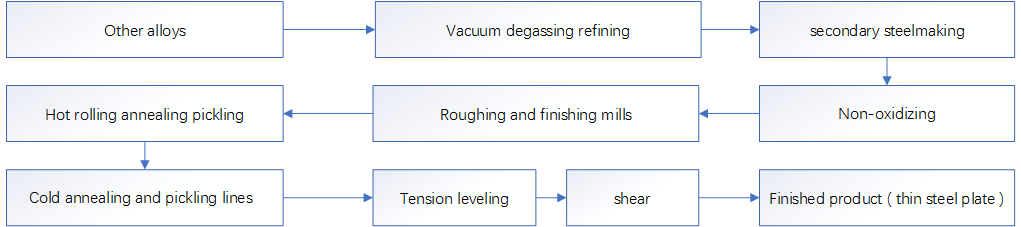

Huanyuchang is the general agent for Japanese metallurgical steel plates in South China, specializing in the deep processing of steel plates for PCB, CCL, IC carrier boards, and other industrial applications. We offer two main types of steel plates:

Ordinary Steel Plate (NAS630): A precipitation hardening steel plate with standard expansion properties.

High Expansion Coefficient Steel Plate (NAS301): Designed for applications requiring higher thermal expansion.

Our company boasts its own processing center and production team, providing customers with a one-stop service that includes sales, processing, and maintenance. This comprehensive approach helps improve product quality and reduce costs for our clients.

We are committed to delivering high-precision technology and maintaining a serious, customer-focused attitude to ensure satisfaction across all projects.

Projects Undertaken:

Pressing steel plate processing, leveling, grinding, polishing, trimming, repair

Usage : Used for PCB, CCL, FCCL, FPCB, aluminum substrate and other factories.

Our Company service guarantee include the following aspects :

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

Service process assurance : Develop and implement standardized service processes to ensure service quality and efficiency. Continuously improve and optimize the service process according to customer feedback and market changes.

Service security : establish a sound information protection mechanism to protect the security and privacy of customer information. Take the necessary safety measures to ensure the personal and property safety in the service process.

After-sales service guarantee : after the end of the service, continue to provide customers with the necessary support and help to solve possible problems. Establish a customer satisfaction survey mechanism, through regular customer satisfaction surveys, to understand customer evaluation and feedback on services, in order to continuously improve service quality.

Through the above measures, the company can provide a full range of service guarantee to ensure customer satisfaction.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More