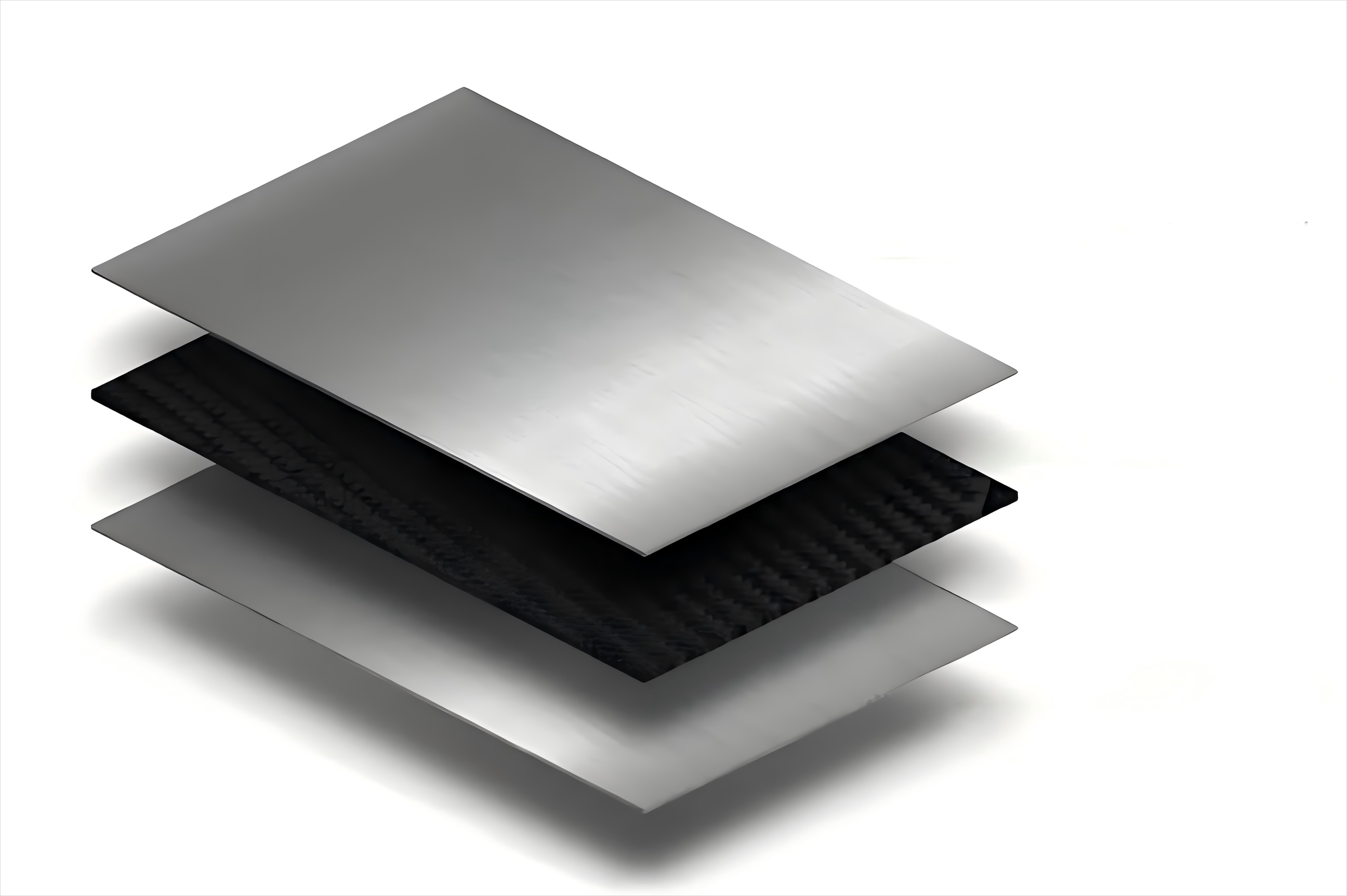

The NAS630 steel plate is a high - performance laminated material, widely used in fields such as electronics, automotive, and aerospace. Its functional characteristics and compositional features give it significant advantages during the lamination process.

·High mechanical strength: During the lamination process, the NAS630 steel plate can withstand high pressure and shear forces, ensuring that the laminated material has high strength and durability, which is suitable for high - load application scenarios.

·The NAS630 steel plate contains a resin matrix with high insulation performance. During the lamination process, the NAS630 steel plate can effectively isolate the current and prevent electrical short - circuits, making it suitable for insulation lamination applications in electronic and electrical equipment.

·The surface of the NAS630 steel plate is specially treated, featuring good wettability and adhesiveness. During the lamination process, the NAS630 steel plate can form a firm bonding interface with other materials (such as metals, ceramics, or plastics), improving the overall performance of the laminated structure.

·The resin matrix and reinforcing materials of the NAS630 steel plate have high fatigue resistance. During the lamination process,

· The NAS630 steel plate uses environmentally friendly resins and harmless reinforcing materials. During the lamination process, the NAS630 steel plate reduces environmental pollution and meets the requirements of modern industry for environmental protection and sustainable development.

High Mechanical Strength:The NAS630 steel plate is designed to withstand high pressure and shear forces during the lamination process, ensuring that the laminated material exhibits exceptional strength and durability. This makes it ideal for high-load application scenarios, such as in construction, heavy machinery, and aerospace industries, where materials are subjected to extreme mechanical stress. The high mechanical strength of the NAS630 steel plate ensures the structural integrity of the final product, even under demanding conditions.

High Insulation Performance:The NAS630 steel plate contains a resin matrix with excellent insulation properties, allowing it to effectively isolate electrical currents and prevent short circuits during the lamination process. This makes it highly suitable for insulation lamination applications in electronic and electrical equipment, such as in circuit boards, transformers, and other high-voltage devices. Its insulation performance ensures the safety and reliability of electrical systems.

Excellent Surface Wettability and Adhesiveness:The surface of the NAS630 steel plate undergoes special treatment, resulting in excellent wettability and adhesiveness. During the lamination process, it forms a strong and durable bonding interface with other materials, such as metals, ceramics, or plastics. This enhances the overall performance of the laminated structure, making it suitable for applications requiring robust material bonding, such as in composite materials and multi-layer structures.

High Fatigue Resistance:The resin matrix and reinforcing materials of the NAS630 steel plate exhibit high fatigue resistance, enabling it to withstand repeated stress cycles during the lamination process. This prevents fatigue failure in the laminated structure, extending the service life of the product. This feature is particularly valuable in applications where materials are subjected to continuous mechanical stress, such as in automotive components and industrial machinery.

Environmentally Friendly Materials:The NAS630 steel plate is manufactured using environmentally friendly resins and non-toxic reinforcing materials, reducing environmental pollution during both production and use. This aligns with modern industry requirements for environmental protection and sustainable development. Its eco-friendly composition makes it suitable for applications in green building projects, renewable energy systems, and other industries prioritizing sustainability.

project | NAS630 | |

Mass-Lam | Pin-Lam | |

Thickness | 1.0~2.5mm | 1.0~2.5mm |

Width | ≦1300mm | ≦1300mm |

Length | ≦2410mm | ≦2410mm |

Plate thickness tolerance | ±0.05mm | ±0.05mm |

Roughness | Ra≦0.15㎛ Rz≦1.5㎛ | Ra≦0.15㎛ Rz≦1.5㎛ |

Hole-to-hole tolerances for positioning holes | -- | +0.1/-0mm |

Standard bushing slot hole tolerances | -- | +0.05/-0mm |

Warpage degree | ≦3mm/m | ≦3mm/m |

Dimension tolerances | -0/+1mm | -0/+1mm |

Endurance | ≧1175(N/mm²) | ≧1175(N/mm²) |

Tensile strength | ≧1400(N/mm²) | ≧1400(N/mm²) |

Extensionality | ≧5% | ≧5% |

Hardness ( HRC ) | 50±2 | 50±2 |

Type | C | Si | Mn | Ni | Cr | Mo | Cu | other |

NAS630 | ≦0.07 | ≦1 | ≦1 | 3~5 | 15~17.5 | - | 3~5 | Nb0.15~0.45 |

Steel plate type | Project | Scope of application | Standard value |

NAS630 | specific gravity |

| 8.03 |

mean coefficient of thermal expansion (10-6/℃) | 0-400℃ | 10~12 |

Steel plate type | bench markW/(m*k) | 0-200℃ | 200-400℃ |

NAS630 | 18~23 | 18 | 23 |

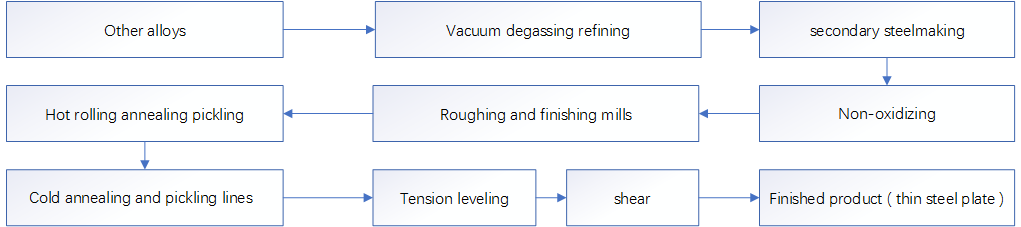

Huanyuchang is the general agent of Japanese metallurgical steel plate in South China.

Specializing in the deep processing of PCB, CCL, IC carrier board and other industrial use of the laminated steel plate

There are two types of steel plates : ordinary steel plate ( NAS630 precipitated hardening steel plate ) and high expansion coefficient steel plate ( NAS301 precipitated hardening steel plate ).

The company has its own processing center and production team, which can provide customers with one-stop service of vehicle, sales, processing and maintenance, so as to help improve customer quality and reduce customer cost.

We sincerely, honest, high-precision technology, a serious attitude towards each customer, so that we are satisfied with both customers.

Projects undertaken :

Pressing steel plate processing, leveling, grinding, polishing, trimming, repair

Usage : Used for PCB, CCL, FCCL, FPCB, aluminum substrate and other factories.

The company adheres to the concept of scientific and technological innovation to promote the continuous development of the company.

It has won a total of 50 patents such as inventions, utility models and appearances issued by the National Intellectual Property Office, and has obtained IS09001 : 2015, national high-tech enterprises and specialized and special new certifications. The company not only pays attention to the improvement of technical quality, but also has a strong logistics capability. The logistics network covers the world.

There are top logistics companies such as Leapfrog, DHL, SF, and Debang that cooperate at home and abroad.

They can track and monitor goods in real time and effectively. To provide a full range of protection for your goods, you can ensure that your goods are delivered safely in the shortest possible time, and have strict quality assurance to provide you with the most assured choice.

In addition, we rely on the industry 's rich experience and skills, cleverly arrange cargo loading, so that it can achieve the highest loading rate in a limited space, saving customers every point of logistics costs.

Henan Huanyuchang Electronic Technology Co., Ltd.is not only committed to its own development, but also strives to give back to the society. It is a caring and socially responsible enterprise.

The company provides scholarships, grants and jobs for talents in colleges and universities, actively invests in public welfare undertakings, organizes public welfare activities, sends warm condolences to grass-roots sanitation workers, and overcomes difficulties during the epidemic.

It participated in various donation activities organized by the government, condoled the staff serving the people and the elders of the nursing home, and always adhered to a strong sense of social responsibility.

Our factory is like a big family, always care about every member ! Organize a variety of knowledge training and professional lectures for employees, such as fire training and exercises to enable employees to learn to penetrate into work and life.

In addition, the company also distributes various rich and colorful benefits such as Dragon Boat Festival, Mid-Autumn Festival and Spring Festival to employees on the occasion of various festivals. At the end of the year, employees will hold a year-end event to strengthen the core cohesion of our team, review the past, look forward to the future, and create brilliant achievements with the company !

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More