1.Product introduction

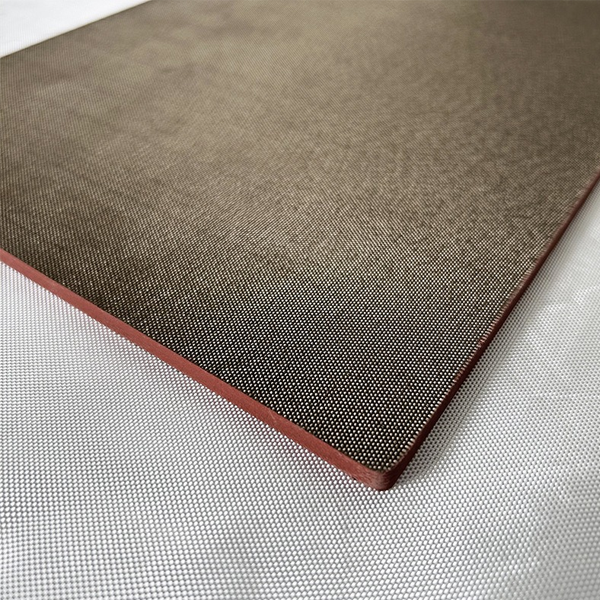

Our Lamination Pad, with its excellent dimensional stability and outstanding cushioning performance, enables efficient operation of uniform temperature and pressure. It completely gets rid of the troubles of debris falling and steel plate adhesion, and eliminates the phenomenon of bubble residue. It takes the lead in environmental protection and is pollution - free, with a prominent cost - effectiveness advantage. Its cushioning performance is first - class. It can be used repeatedly 200 - 500 times, strongly replacing kraft paper. The single - use cost drops sharply, and automated operation comes naturally.

2.Component

The Lamination Pad makes a stunning debut, relying on the elastic potential of high - elastic fibers, the practical properties of anti - sticking and high - temperature - resistant reinforcement materials, and the magic of integration of high - molecular polymers.

3.Feature and Application

The Lamination Pad is mainly used in lamination processes for PCB, CCL, new energy battery panels, etc.

In the production of aerospace models, the Lamination Pad serves as a "precision safeguard". For the lamination of light and thin aerospace materials, it ensures the structural stability of the model with minimal buffering error. At the same time, it can adapt to the special high - temperature processes in model making, ensuring the precise formation of the model and meeting the enthusiasts' pursuit of details and performance. When it comes to the lamination of the casings of industrial automation control equipment, the lamination buffer pad acts as a "precision protector". When the casings of power distribution cabinets and control cabinets are being formed, it protects the internal electrical components from the impact of lamination. Meanwhile, it can meet the requirements of high temperature and dust in the industrial environment. By providing stable buffering, it ensures the reliable operation of the equipment and contributes to the efficient progress of industrial production.

4. About us

Henan Huanyuchang Electronic Technology Co., Ltd. is a comprehensive enterprise integrating R&D, production and sales, committed to CCL, PCB, FPCB, aluminum substrate and other pressed high-temperature materials. In order to adapt to the new 5G materials and high standards of pressing conditions in the electronics industry, and comply with the environmental protection trend in the industry, our company launched a high-temperature buffer material instead of kraft paper - Navis pad, the product is more resistant to high temperature, can work for a long time at a temperature of 150°C-400°C, no carbonization, no brittleness, good buffering effect, good heat conduction uniformity, stable pressing expansion and contraction, production thickness 1~10mm, can meet customer needs to match, intelligent record times. The company also has other special products for pressing, such as: special bearing discs for pressing, imported metallurgical steel plates and other products.

The company adheres to the concept of scientific and technological innovation to promote the continuous development of the enterprise, and has won a total of 50 patents for inventions, utility models and appearances issued by the State Intellectual Property Office, and has obtained the certification of ISO9001:2015 and national high-tech enterprises.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More