1.Product introduction

The lamination cushion has good buffering performance. Compared with the kraft paper used in most lamination processes, its shock - absorption and buffering performance is 12% higher than that of kraft paper.

The press pad is suitable for high - temperature environments. The high - temperature - resistant lamination pad material can continuously work in a high - temperature environment of 280°C. The lamination cushion has good heat - conduction performance and uniform heat transfer, which improves the production efficiency of high - temperature lamination.

During the production process, the lamination cushion undergoes repeated pressing and polishing to ensure uniform thickness, flatness and consistency.

Under normal temperature conditions, the surface of the lamination cushion is relatively hard. Under high - temperature conditions, its buffering performance is stable, which is conducive to the stable pressing and forming of the hot - pressing process.

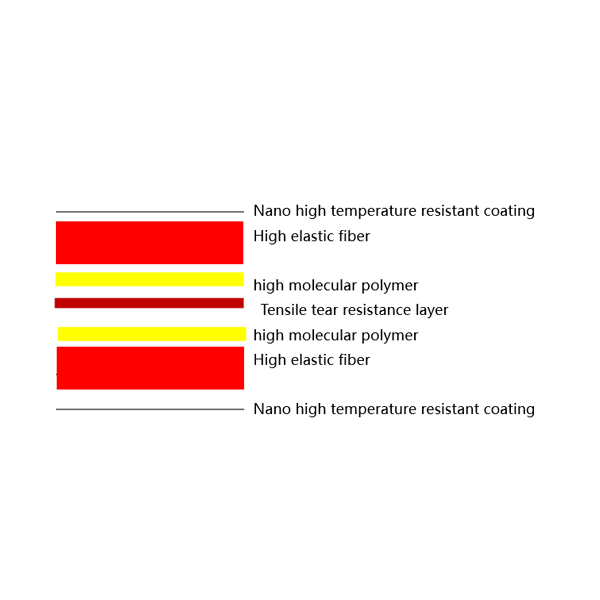

2.Component

The high temperature resistant buffer pad is made of high elastic fiber, anti-stick high temperature resistant reinforcing material and high molecular polymer. It has excellent high temperature resistance, tear resistance, shock absorption and buffering protection performance.

3.Feature and Application

It is mainly used in lamination processes for CCL, aluminum-based substrates, furniture panels, PCB, HDI, high-frequency and high-speed boards, FCCL, solar panels, liquid crystal panels, etc. It is currently the best product to replace kraft paper and silicone pads.

The press pad is like an "all-round craftsman", showing its prowess in the electronics industry. During the lamination of circuit boards, with its excellent buffering performance, it shelters tiny and precise electronic components from the "storm", withstanding strong lamination pressure. Its high-temperature resistance makes it fearless of the roasting of high-temperature processes, ensuring the perfect formation of circuit boards. It is an indispensable key support in electronics manufacturing. In the furniture field, it transforms into a "flatness master". Whether it is the lamination process of plywood, fiberboard, or solid wood panels, it can, with its uniform and stable buffering force, make the panels fit tightly together, eliminating defects such as bulging and delamination, and enhancing the quality and grade of furniture.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More