Product introduction

1. The Laminated Cushion has excellent high - temperature resistance and can work at 260℃ for a long time without carbonization or embrittlement.

2. It features superior buffering effect, uniform heat conduction, stable expansion and contraction, consistent expansion coefficient, and is tear - resistant.

3. It has good flame - retardant performance, its components are non - toxic and odorless. It enables dust - free construction and has good air permeability.

4. It is pressure - resistant and can be used multiple times, offering high cost - effectiveness. The number of usage times ranges from 200 to 500, which reduces losses and cuts costs by 20 - 30%.

5. It is independently developed. The thickness (1.0 - 10 mm) can be customized according to production needs, and the performance can be enhanced. There is 24 - hour technical support available. It can be equipped with intelligent usage - times tracking to remind users to replace the buffer pad in a timely manner.

6. It is self - produced, ensuring a short delivery time.

1.Exceptional High-Temperature Resistance: The Laminated Cushion is designed to withstand extreme temperatures up to 260℃ for prolonged periods without carbonization or embrittlement, ensuring durability in high-heat environments.

2.Superior Buffering and Heat Conduction: With excellent buffering capabilities, it ensures uniform heat distribution, stable expansion and contraction, and a consistent expansion coefficient. Its tear-resistant properties make it ideal for demanding industrial applications.

3.Flame-Retardant and Eco-Friendly: The cushion boasts flame-retardant properties and is made from non-toxic, odorless materials. It supports dust-free construction and offers excellent air permeability, making it suitable for cleanroom environments.

4.Pressure-Resistant and Cost-Effective: Designed for repeated use, it can withstand 200 to 500 cycles, reducing material loss and cutting costs by 20%-30%. Its reusability makes it a sustainable and economical choice.

5.Customizable and Intelligent: Independently developed, the cushion’s thickness (1.0-10 mm) can be tailored to specific production needs. Enhanced performance options are available, along with 24/7 technical support. An intelligent usage-tracking feature can be added to remind users when to replace the cushion.

6.Self-Produced for Fast Delivery: Manufactured in-house, the product ensures quick turnaround times, meeting urgent production demands.

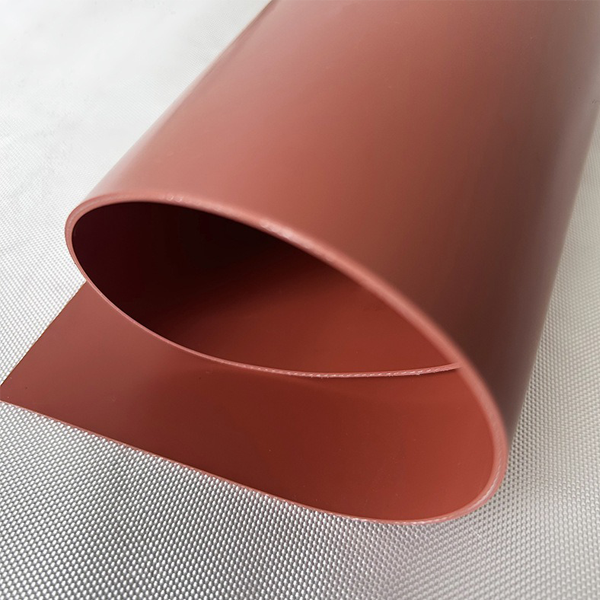

Component

This product is composed of highly elastic fibers, anti - sticking and high - temperature - resistant reinforcement materials, and high - molecular polymers, and it has excellent performance.

The Laminated Cushion is composed of highly elastic fibers, anti-stick and high-temperature-resistant reinforcement materials, and high-molecular polymers. This unique combination delivers exceptional performance across various industrial applications.

Feature and Application

It is mainly used in lamination processes for CCL, aluminum-based substrates, PCB, HDI, high-frequency and high-speed boards, FCCL, solar panels, liquid crystal panels, the middle layer (thin board) of PCB, flexible-rigid printed circuit boards (FPCB), and the middle layer (thin board) of PCB, as well as in the film pressing of new energy batteries, etc. Currently, it is the best product to replace kraft paper and silicone pads.

The Laminated Cushion is widely used in lamination processes for:

l CCL (Copper Clad Laminate)

l Aluminum-based substrates

l PCB (Printed Circuit Boards)

l HDI (High-Density Interconnect)

l High-frequency and high-speed boards

l FCCL (Flexible Copper Clad Laminate)

l Solar panels and liquid crystal panels

l Middle layers of PCB (thin boards)

l Flexible-rigid printed circuit boards (FPCB)

l New energy battery film pressing

It is currently the best alternative to traditional kraft paper and silicone pads, offering superior performance and versatility.

The Press Pad is like an “industry lubricant”, making the operation of many industries smoother. In the field of electronics manufacturing, during the circuit board lamination process, it protects electronic components with precise buffering. Its high-temperature resistance allows it to handle high-temperature process steps with ease, ensuring the stable performance of electronic products. In furniture manufacturing, it serves as a “stabilizer” for board lamination. Wood and artificial boards, buffered by it, fit tightly together, eliminating quality problems and improving furniture quality. In automotive interior production, when facing the high-temperature and high-pressure molding of dashboards, door interior panels, etc., it provides precise buffering, resists heat, and prevents wrinkling, ensuring the exquisite and flawless appearance of the interior. In the packaging and printing field, for the lamination and film covering of hardcover book covers and high-end packaging boxes, it provides buffering support, protects graphics and text, and promotes adhesion, meeting the needs of high-quality packaging. In the photovoltaic industry, during the encapsulation and lamination of solar panels, it adapts to high temperatures, ensures the stability of solar cells, and improves the power generation efficiency and service life of photovoltaic modules.

1. Electronics Manufacturing: During circuit board lamination, the cushion provides precise buffering to protect electronic components. Its high-temperature resistance ensures stable performance in high-heat processes.

2. Furniture Manufacturing: Acting as a “stabilizer” for board lamination, it ensures tight bonding between wood and artificial boards, eliminating quality issues and enhancing furniture durability.

3. Automotive Interior Production: In high-temperature and high-pressure molding of dashboards and door panels, the cushion prevents wrinkling and ensures a flawless finish for automotive interiors.

4. Packaging and Printing: For laminating hardcover book covers and high-end packaging boxes, it offers buffering support, protects graphics, and promotes adhesion, meeting premium packaging standards.

5. Photovoltaic Industry: During solar panel encapsulation and lamination, the cushion adapts to high temperatures, ensuring the stability of solar cells and improving the efficiency and lifespan of photovoltaic modules.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More