1.Product introduction

1. The Lamination Process Materials is like the "buffering guard" for lamination operations. Compared with the kraft paper widely used in lamination processes, with its shock - absorption and buffering performance exceeding that of its competitor by 12%, easily handling various buffering challenges.

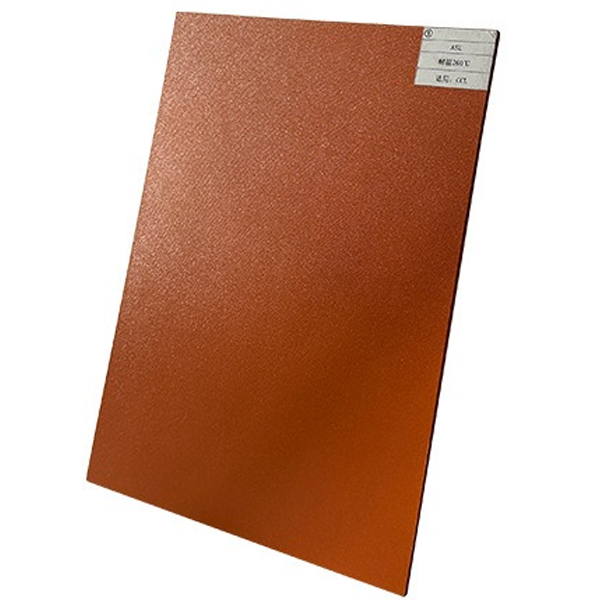

2. The Lamination Process Materials can be regarded as a "hard - core tool" in high - temperature environments. With the support of high - temperature - resistant lamination pad materials, it remains as stable as Mount Tai under the severe test of 280°C high temperature, continuously exerting its force. With its uniform and efficient heat - conduction performance, it boosts the production efficiency of high - temperature lamination significantly.

3. Every Lamination Process Materials embodies craftsmanship and sweat. The repeated pressing and polishing in the production process is like a tempering process, resulting in its impeccable thickness uniformity, flatness, and consistency, laying a solid foundation for your lamination process.

4. The unique Lamination Process Materials has a dual charm. In normal - temperature environments, its hard surface safeguards and simplifies the process. Under high - temperature working conditions, its buffering potential fully explodes. With its stable performance, it escorts the stable pressing and forming of the hot - pressing process, enabling your production to proceed at full speed.

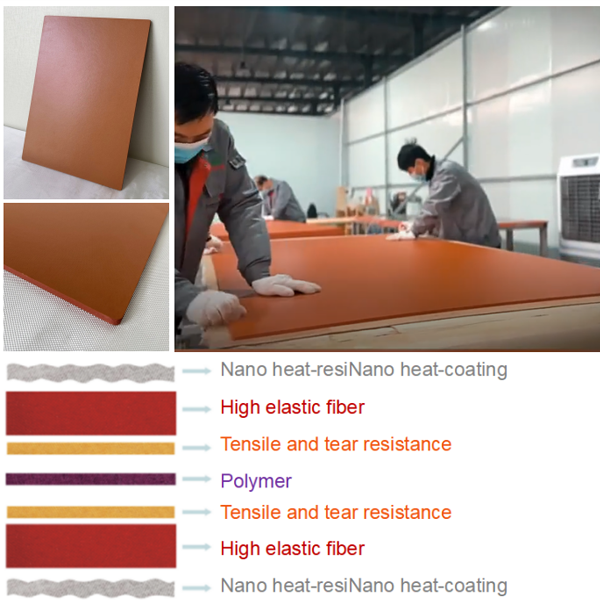

2.Component

This Lamination Process Materials is extraordinary. It is based on high - elastic fibers, incorporates anti - sticking and high - temperature - resistant reinforcement materials, and is carefully compounded with high - molecular polymers, fully demonstrating its high quality.

3.Feature and Application

It is mainly used in the lamination processes of CCL, aluminum-based substrates, furniture panels, PCB, HDI, high-frequency and high-speed boards, FCCL, solar panels, liquid crystal panels, etc. At present, it is the best product to replace kraft paper and silicone pads. The Lamination Process Materials is like a master key, opening the door to high-quality production in numerous industries. In the electronics manufacturing industry, it is the "guardian" of circuit board lamination. With its excellent buffering performance, it withstands lamination pressure to ensure that electronic components remain intact. Its high-temperature resistance enables it to operate smoothly in the high-temperature processes of electronics manufacturing, guaranteeing the outstanding performance of electronic products. In the furniture manufacturing industry, it is the "quality enforcer" for board lamination. Whether it is the lamination processing of plywood, particleboard, or solid wood boards, it can use its outstanding buffering force to make the boards fit tightly together, eliminating quality risks and creating beautiful and durable furniture. In the automotive interior production field, when facing the high-temperature and high-pressure lamination and molding of dashboards, door interior panels, etc., it provides precise buffering, resists heat and prevents wrinkling, making the automotive interior extremely delicate and enhancing the overall grade of the vehicle.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More