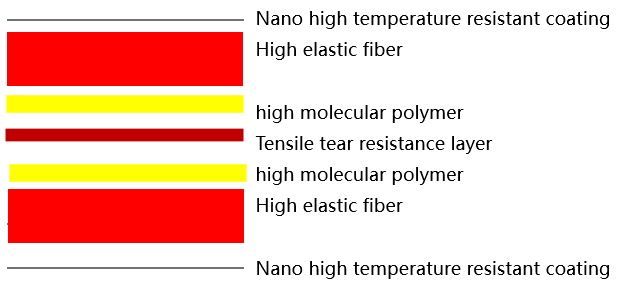

Following the successful launch of cushioning pads for the CCL industry, we are proud to introduce our latest innovation: high-performance cushioning pads specifically designed for the PCB and IC carrier board industries. Crafted from a unique blend of high-elastic fibers and advanced polymers, these next-generation cushioning pads deliver superior durability and enhanced cushioning performance compared to their predecessors. Engineered to meet the rigorous demands of modern manufacturing processes, they ensure optimal protection and reliability in high-temperature and high-pressure environments.

| Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations | |

| Coffee color soft pad /hard pad is suitable for lithium battery, heating piece | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 10000-16000 |

| silicone pad | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 4000 |

Excellent ★ Good ❏ Poor⊙

This product stands as the ultimate replacement for traditional kraft paper and silicone pads. It is specifically designed for use in the pressing processes of lithium batteries and heating sheets. With its excellent thermal conductivity, it effectively addresses common industry challenges such as thick copper layers, low residual copper rates, and bubble formation. Ideal for high-precision applications, it ensures superior performance and reliability in demanding manufacturing environments.

1.More resistant to high temperature, can work at 260 ° C for a long time, not carbonized, not brittle ;

2.The buffer effect is good, the heat conduction uniformity is good, the compression shrinkage is stable, the expansion coefficient of the product is stable, and the tear resistance is good ;

3.withstanding pressure ( can be pressed 10000-16000 times ), flame retardant, non-toxic and odorless, dust-free and dust-free, good permeability ;

4.Independent research and development, independent production, short production cycle, equipped with faster technical services ;

the production thickness is 1.0 ~ 10mm, which can meet the customer 's needs and record the number of times intelligently ;

6.High quality cost performance.

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

| Compare Item 1 | Navies pad | silicone pad | Compare Item 2 | Navies pad | silicone pad |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

Our company offers tailored cost-saving solutions based on the specific needs of our customers. By replacing conventional kraft paper with our advanced cushioning pads, we have demonstrated cost reductions of 10-20% across our current customer base. This innovative solution not only enhances performance but also delivers significant economic benefits, making it a smart investment for optimizing production efficiency.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More