1.Product introduction

The press pad has profound buffering capabilities. When compared with the commonly used kraft paper in the lamination process, its advantages are immediately apparent. Its shock absorption and buffering performance is a full 12% higher than that of kraft paper, providing a more reliable guarantee for your lamination operations.

The press pad is "tailor - made" for high - temperature environments. The high - temperature - resistant lamination pad material it uses has excellent performance. Even when placed in a high - temperature "oven" of 280°C, it can still work stably and continuously. It has excellent heat conduction performance and uniform heat transfer, as if installing an "accelerator" for the production efficiency of high - temperature lamination.

In the process of its production, the press pad has gone through numerous "ordeals". The repeated pressing and polishing processes are like fine carvings, all aiming to present you with a high - quality product with uniform thickness, flatness, and extremely high consistency. This ensures that every use is precise and error - free, strictly controlling the quality of your production.

The press pad has a unique "temperament". Under normal temperature conditions, its surface is slightly tough, facilitating daily operations such as handling and storage. However, once it enters a high - temperature environment, it quickly "awakens" and releases stable and powerful buffering performance. It is as if it is tailor - made for the hot - pressing process, stably pressing and forming to fully meet your production needs.

2.Component

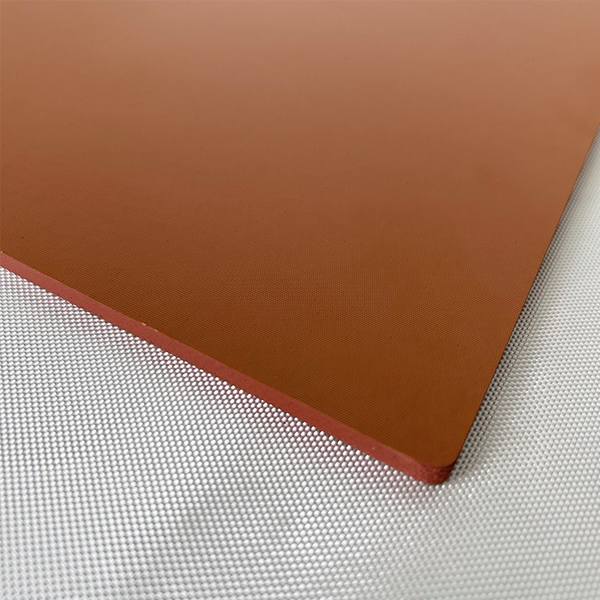

press pad press pad. It is exquisitely compounded from high - elastic fibers, super anti - sticking and high - temperature - resistant reinforcement materials, combined with high - molecular polymers, presenting outstanding quality.

3.Feature and Application

It is mainly used in the lamination processes of CCL, aluminum-based substrates, furniture panels, PCB, HDI, high-frequency and high-speed boards, FCCL, solar panels, liquid crystal panels, etc. At present, it is the best product to replace kraft paper and silicone pads.

This press pad has a very wide range of applications. In the electronics manufacturing workshop, during the lamination process of circuit boards, it precisely buffers to protect electronic components, just like putting protective clothing on the fragile electronic world. At the same time, with its excellent high-temperature resistance, it remains as stable as Mount Tai in high-temperature processes, ensuring the reliability of electronic products. In the furniture manufacturing factory, it becomes a capable partner for the lamination of various types of boards. For the lamination of multi-layer solid wood composite boards, decorative boards, etc., it helps achieve smooth and flat results, avoiding board deformation and contributing to the production of high-quality furniture. Moreover, on the automotive interior production line, when facing the high-demanding lamination and molding of dashboards, door interior panels, etc., it buffers precisely, effectively resists high temperatures and pressures, ensures that the interior is exquisite and wrinkle-free, and meets the high-end quality requirements of automobiles.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More