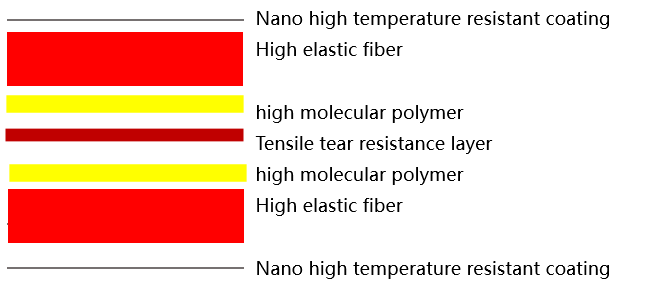

After the introduction of cushioning pads for CCL industry, we have developed cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation of cushioning pads.

| Performance Category | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Coffee color soft pad /hard pad is suitable for lithium battery, heating piece | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 10000-16000 |

| silicone pad | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 4000 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the pressing process of lithium battery and heating sheet. It has good thermal conductivity and can solve the problems of thick copper, low residual copper rate and bubble.

Exceptional High-Temperature Resistance

This product is engineered to excel in extreme thermal environments, offering unparalleled high-temperature resistance. It can operate continuously at temperatures up to 260°C without undergoing carbonization or becoming brittle. This ensures long-term durability and reliability, even under the most demanding conditions.

Key Features:

Thermal Stability: Maintains structural integrity and performance at sustained high temperatures.

Non-Carbonizing: Resists carbonization, preventing degradation and maintaining smooth operation.

Non-Brittle: Retains flexibility and strength, avoiding brittleness that could lead to cracking or failure.

Ideal for applications such as lithium battery pressing, heating sheet processes, and other high-temperature industrial operations, this product delivers consistent performance and extends the lifespan of equipment and materials. Its ability to withstand extreme heat makes it a superior alternative to traditional materials like kraft paper and silicone pads.

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

| Compare Item 1 | Navies pad | silicone pad | Compare Item 2 | Navies pad | silicone pad |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

According to the actual situation of customers, our company formulates a cost saving scheme, which can save 10-20 % cost compared with conventional kraft paper according to the current customer base.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More