1.Product introduction

1. Among numerous lamination buffer products, the Lamination Process Materials is definitely a top performer. Its buffering performance is first - rate. Compared with the kraft paper used in most lamination processes, its shock - absorption and buffering efficiency leads by a whopping 12%. It is the perfect choice for you to pursue high - quality lamination results.

2. No need to worry about high - temperature working conditions, as the Lamination Process Materials is here to solve the problem. The high - temperature - resistant material it selects is ingeniously designed. At the sweltering temperature of 280°C, it fearlessly continues to operate efficiently. With its excellent heat - conduction uniformity, it helps the production efficiency of high - temperature lamination soar.

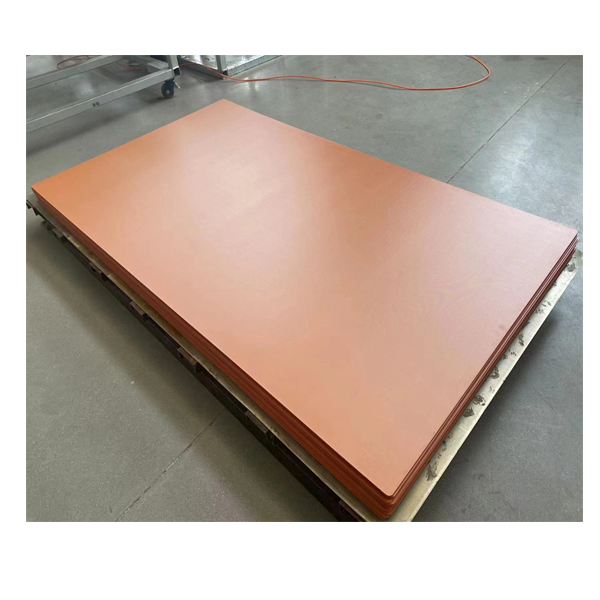

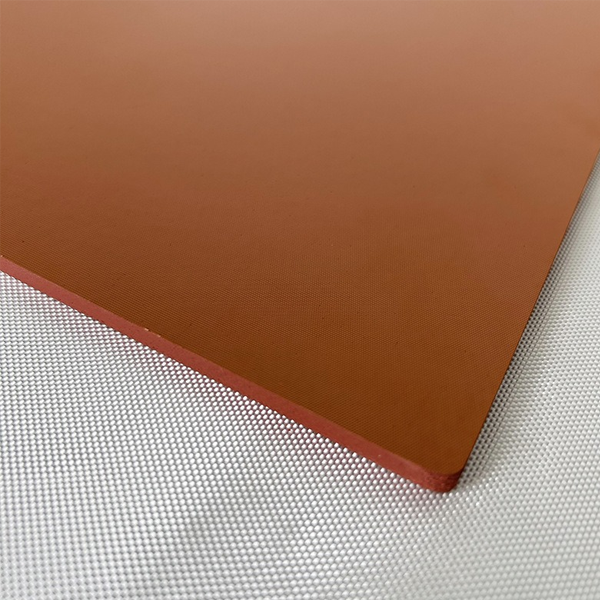

3. Every Lamination Process Materials embodies craftsmanship and hard work. The repeated pressing and polishing in the production process is like a tempering process, resulting in its impeccable thickness uniformity, flatness, and consistency, laying a solid foundation for your lamination process.

4. The performance of the Lamination Process Materials is truly stunning. It presents a hard surface at normal temperature, facilitating your pre - processing procedures. When the temperature rises, its buffering performance bursts out instantly, stably assisting the hot - pressing process to form, and it is a reliable assistant for you to pursue efficient production.

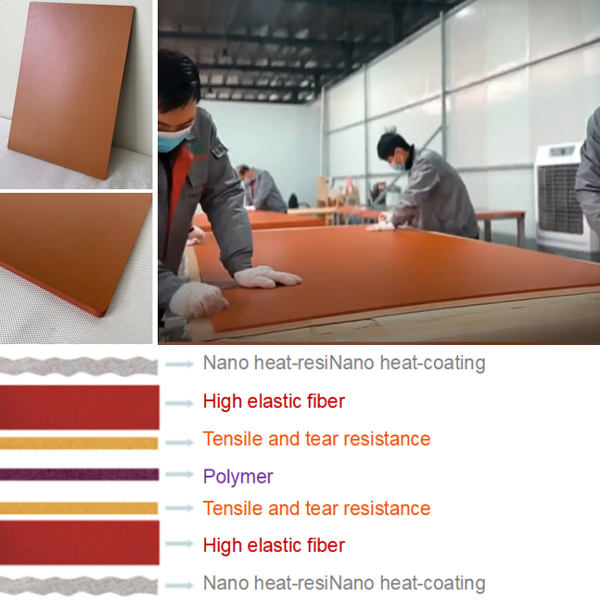

2.Component

The Lamination Process Materials is ingeniously compounded by combining high - elastic fibers, high - temperature - resistant and anti - sticking reinforcing materials that are highly effective, and high - molecular polymers, demonstrating extraordinary capabilities.

3.Feature and Application

It is mainly used in the lamination processes of CCL, aluminum - based substrates, furniture panels, PCB, HDI, high - frequency and high - speed boards, FCCL, solar panels, liquid - crystal panels, etc. At present, it is the best product to replace kraft paper and silicone pads.

The applicable scope of the Lamination Process Materials spans multiple industries. In the high - tech electronics field, during the lamination of circuit boards, its powerful buffering performance resists external pressure and protects the hair - like fine electronic components. Its high - temperature resistance enables it to remain in operation even in a high - temperature process environment of 280°C, escorting electronic products from design blueprints to reality. Switching to the home building materials scenario, for the lamination and bonding of wooden and artificial boards, it is the top choice. With its uniform buffering force, it enables seamless docking of the boards, improves the overall strength of the boards, and builds a solid quality foundation for home products. Entering the automotive interior manufacturing workshop, components such as dashboards and door interior panels are formed under high temperature and high pressure. The Lamination Process Materials, with its stable buffering performance and high - temperature resistance advantages, prevents the deformation of interior materials and endows automotive interiors with a luxurious texture.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More