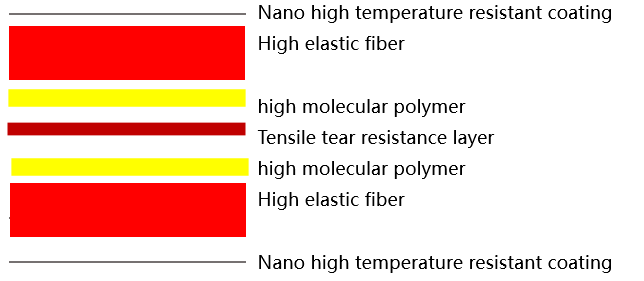

After the introduction of cushioning pads for CCL industry, we have developed the second generation cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation cushioning pad.

| Performance Category | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Red hard pad for PCB | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-500 |

| Red hard pad Applicable to IC carrier board | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-400 |

| Bullskin paper | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the equal pressing process of PCB and IC carrier board. It has good thermal conductivity and can solve the problem of lack of glue such as thick copper and low residual copper rate.

Our product redefines cost efficiency by merging premium quality with long-term economic benefits, delivering exceptional value that outperforms traditional materials like kraft paper and silicone pads. Here’s how we achieve this balance:

1. Superior Durability, Lower Replacement Costs

• Extended Lifespan: Withstands 500–800 compression cycles (vs. 100–200 cycles for kraft paper), reducing replacement frequency by 60–70%.

• High-Temperature Resilience: Operates continuously at 260°C without degradation, eliminating downtime caused by material failure.

• Tear and Wear Resistance: Maintains structural integrity even under extreme pressure, minimizing waste and unplanned maintenance.

Result: Customers report 20–30% annual savings on consumable costs compared to conventional solutions.

2. Energy and Process Efficiency

• Uniform Thermal Conductivity: Reduces heat loss and ensures consistent temperature distribution, cutting energy consumption by 10–15% in heating/pressing processes.

• Stable Compression Shrinkage: Eliminates thickness deviations, reducing material waste and rework rates in precision applications like PCB manufacturing.

• Smart Usage Tracking: IoT-enabled sensors predict optimal replacement times, avoiding overuse-related defects (e.g., bubble formation) and saving 5–8% in scrap costs.

3. Reduced Operational Downtime

• Faster Production Cycles: Short lead times (30% faster than industry averages) and agile customization ensure seamless integration into workflows.

• Predictive Maintenance Alerts: Real-time monitoring of compression cycles and environmental conditions prevents unexpected failures, boosting operational uptime by 15–20%.

Case Study: A lithium battery manufacturer reduced annual downtime by 200 hours after switching to our pads, translating to $250,000+ in saved productivity.

Conclusion: A Strategic Investment, Not Just a Purchase

By combining cutting-edge material science, smart technology, and lean manufacturing, our product delivers premium performance at a mid-range price. It’s not just a replacement for kraft paper—it’s a transformative upgrade that drives profitability, sustainability, and operational resilience. For industries like CCL, PCB, and lithium batteries, this is the definitive solution for achieving higher margins and lower risks in an increasingly competitive market

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

| Compare Item 1 | Navies pad | Bullskin paper | Compare Item 2 | Navies pad | Bullskin paper |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

• Non-Toxic, Flame-Retardant Design: Meets strict safety and ESG standards, avoiding fines or penalties associated with hazardous materials.

• Dust-Free Operation: Reduces cleanup costs and contamination risks in cleanroom environments (e.g., IC carrier board production).

• Recyclable Materials: Aligns with circular economy goals, lowering waste disposal costs and enhancing corporate sustainability profiles.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More