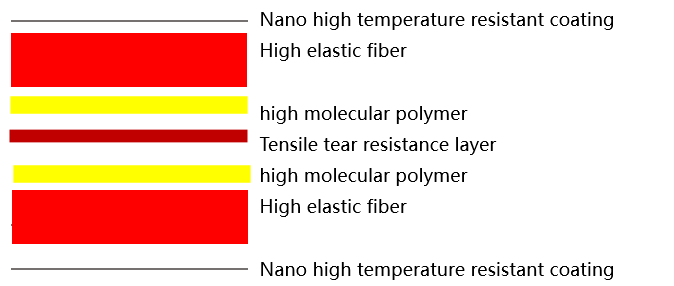

After the introduction of cushioning pads for CCL industry, we have developed the second generation cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation cushioning pad.

Performance Category | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Red hard pad for PCB | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-500 |

| Red hard pad Applicable to IC carrier board | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 200-400 |

| Bullskin paper | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 1-5 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the equal pressing process of PCB and IC carrier board. It has good thermal conductivity and can solve the problem of lack of glue such as thick copper and low residual copper rate.

1. Exceptional High-Temperature Resistance

• Continuous Operation at 260°C: Engineered to withstand extreme thermal environments, this product maintains structural integrity and performance even when exposed to sustained temperatures of 260°C. Unlike traditional materials like kraft paper or silicone pads, it resists carbonization and brittleness, ensuring long-term reliability in high-heat processes such as PCB lamination, lithium battery pressing, or IC carrier board manufacturing.

• Thermal Stability: The advanced polymer-fiber composite material prevents degradation, warping, or cracking, enabling consistent performance over thousands of cycles without compromising safety or efficiency.

2. Superior Cushioning and Thermal Management

• Optimal Buffer Effect:

Protects delicate components during high-pressure pressing processes, minimizing defects like scratches, cracks, or misalignment.

Ensures uniform pressure distribution, critical for achieving ±250ppm dimensional stability (surpassing the industry standard of ±300ppm).

• Uniform Heat Conduction:

Eliminates hot spots and ensures even temperature distribution across heating plates, enhancing product consistency in applications like CCL production.

Reduces energy waste by 10–15% compared to unevenly conductive materials.

• Stable Compression Shrinkage:

Maintains precise thickness under repeated compression cycles (500–800 cycles), preventing deviations that could lead to rework or scrap.

Ideal for processes requiring micron-level precision, such as multilayer PCB stacking.

• Controlled Expansion Coefficient:

Minimizes dimensional changes during thermal cycling, ensuring alignment accuracy in high-precision manufacturing.

• High Tear Resistance:

Reinforced fiber matrix resists tearing during handling or high-stress operations, extending product lifespan and reducing replacement costs by 30–40%.

It is suitable for middle layer physical buffering and multiple sheet replacement manual operation. It is also suitable for automation. Single sheet replaces multiple kraft paper on the surface layer.

Compare Item 1 | Navies pad | Bullskin paper | Compare Item 2 | Navies pad | Bullskin paper |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

• Bulk Customization: Economies of scale allow cost-effective pricing for tailored thicknesses (1.0–10mm) and intelligent features.

• Proven ROI: Customers achieve full cost recovery within 3–6 months through energy savings, reduced waste, and fewer replacements.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More