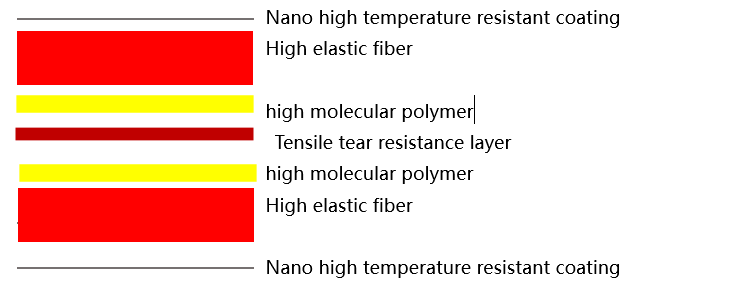

After the introduction of cushioning pads for CCL industry, we have developed cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation of cushioning pads.

PerformanceCategory | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Coffee color soft pad / hard pad is suitable for lithium battery, heating piece | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 10000-16000 |

| silicone pad | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 4000 |

Excellent ★ Good ❏ Poor⊙

This product is currently the best product to replace kraft paper and silicone pad. It is mainly used in the equal pressing process of PCB and IC carrier board. It has good thermal conductivity and can solve the problem of lack of glue such as thick copper and low residual copper rate.

Why Choose Our Product?

For Precision Industries: Achieve micron-level accuracy and stability, reducing rework and improving product quality.

For High-Volume Manufacturers: Minimize downtime and maximize productivity with rapid delivery and responsive technical support.

For Cost-Conscious Businesses: Lower operational costs and extend equipment lifespan, delivering long-term savings.

By combining customizable thickness options, intelligent usage tracking, and high-quality cost performance, our product ensures unmatched reliability, efficiency, and value for industries like CCL, PCB, and lithium battery manufacturing. It’s not just a replacement for traditional materials—it’s a transformative solution that drives profitability and sustainability in modern industrial applications.

Compare Item 1 | Navies pad | silicone pad | Compare Item 2 | Navies pad | silicone pad |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

Customized Cost-Saving Schemes

We understand that every customer’s needs are unique. Our team works closely with clients to analyze their specific processes and challenges, developing tailored solutions that maximize cost efficiency.

Steps in Our Approach:

On-Site Assessment:

Evaluate current material usage, energy consumption, and operational inefficiencies.

Data-Driven Recommendations:

Provide detailed reports on potential savings and ROI based on real-world data.

Implementation Support:

Assist with product integration, training, and process optimization to ensure seamless adoption.

Continuous Improvement:

Monitor performance and provide ongoing support to further enhance cost savings over time.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More