1.Product introduction

The lamination buffer pad can withstand a high temperature of 300℃, but its long - term service life may be reduced.

It has good rigidity and excellent filling ability for large - area open spaces.

In terms of wear resistance and high - temperature resistance, its wear - resistant performance is excellent.

According to the form of the applicable product and the customer's requirements, select the corresponding thickness.

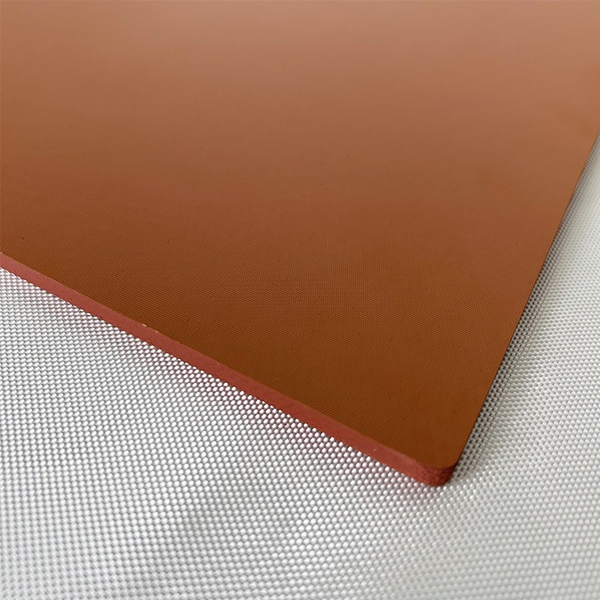

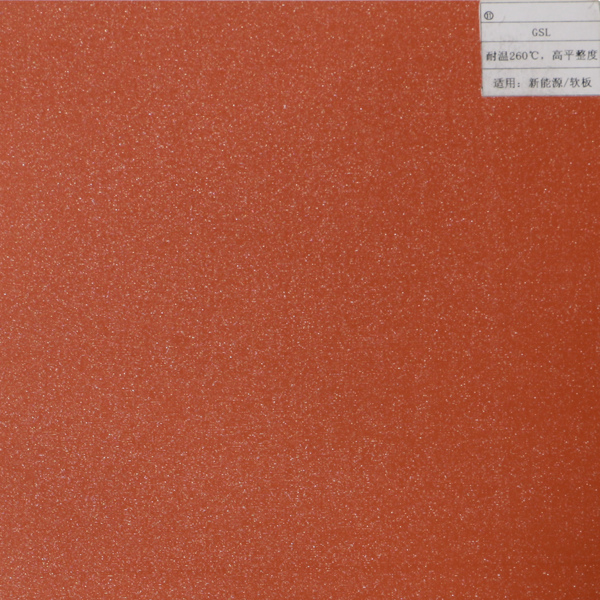

2.Component

The lamination buffer pad is composed of highly elastic fibers, anti - sticking and high - temperature - resistant reinforcement materials, and high - molecular polymers, and it has excellent performance.

3.Feature and Application

The lamination buffer pad is mainly used in lamination processes for PCB, CCL, new energy battery panels, etc.

In the photovoltaic industry, the lamination buffer pad serves as a "green energy escort". The encapsulation and lamination of solar panels are of great significance. It can perfectly adapt to the high - temperature conditions in photovoltaic production. With its stable cushioning performance, it ensures the stability of solar cells during the lamination process, preventing the cells from cracking or shifting, and guaranteeing the power - generation efficiency and service life of photovoltaic modules, thus contributing to the development of clean energy.

4.Staff Welfare

Henan Huanyuchang Electronic Technology Co., Ltd.is not only committed to its own development, but also strives to give back to the society. It is a caring and socially responsible enterprise.

The company provides scholarships, grants and jobs for talents in colleges and universities, actively invests in public welfare undertakings, organizes public welfare activities, sends warm condolences to grass-roots sanitation workers, and overcomes difficulties during the epidemic.

It participated in various donation activities organized by the government, condoled the staff serving the people and the elders of the nursing home, and always adhered to a strong sense of social responsibility.

Our factory is like a big family, always care about every member ! Organize a variety of knowledge training and professional lectures for employees, such as fire training and exercises to enable employees to learn to penetrate into work and life.

In addition, the company also distributes various rich and colorful benefits such as Dragon Boat Festival, Mid-Autumn Festival and Spring Festival to employees on the occasion of various festivals. At the end of the year, employees will hold a year-end event to strengthen the core cohesion of our team, review the past, look forward to the future, and create brilliant achievements with the company !

5.FAQ

Are you a trading company or a manufacturer?

We are a manufacturer.

How can I get a quotation?

Please send us your drawings or details of your requirements, then we will quote to you.

Where is your factory located?

Our factory is located in Runan City, Henan Province.

Can I come and visit you?

Yes, of course. We are pleased to welcome you to visit our company and discuss technical details and requirements with our team.

How does your factory do regarding quality control?

Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More