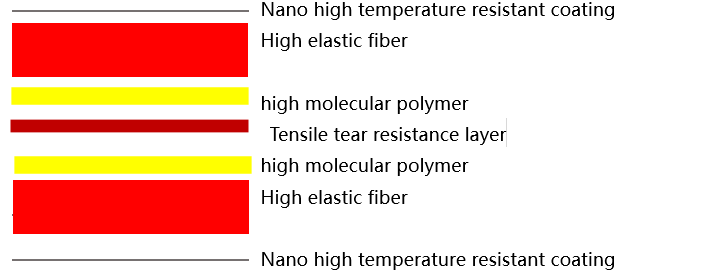

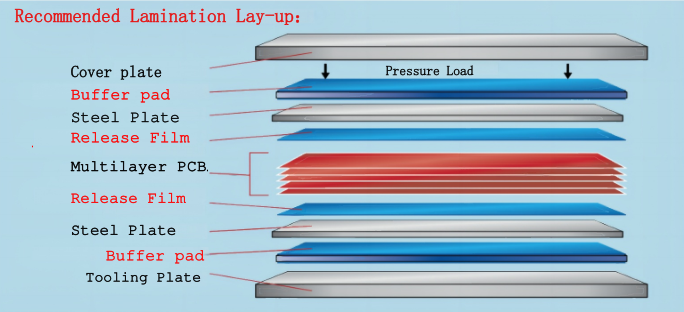

After the introduction of cushioning pads for CCL industry, we have developed cushioning pads for PCB and IC carrier board industry. This product is composed of high elastic fiber and polymer, and the cushioning performance is also improved compared with the first generation of cushioning pads.

PerformanceCategory | Flatness | Roughness | Wear resistance | Size shrinkage | Thickness change | Buffer performance | High temperature resistance | Number of recommendations |

| Coffee color soft pad / hard pad is suitable for lithium battery, heating piece | ★ | ❏ | ★ | ★ | ★ | ★ | ★ | 10000-16000 |

| silicone pad | ❏ | ★ | ❏ | ★ | ❏ | ❏ | ⊙ | 4000 |

Excellent ★ Good ❏ Poor⊙

This product is the ideal solution for industries seeking to optimize their pressing processes, improve product quality, and reduce costs. By replacing outdated materials like kraft paper and silicone pads, it delivers unmatched performance and long-term value in PCB and IC carrier board manufacturing.

1.More resistant to high temperature, can work at 260 ° C for a long time, not carbonized, not brittle ;

2.The buffer effect is good, the heat conduction uniformity is good, the compression shrinkage is stable, the expansion coefficient of the product is stable, and the tear resistance is good ;

3.withstanding pressure ( 200 ~ 500 times ), flame retardant, non-toxic and odorless, dust-free and dust-free, good ventilation effect ;

4.Independent research and development, independent production, short production cycle, equipped with faster technical services ;

the production thickness is 1.0 ~ 10mm, which can meet the customer 's needs and record the number of times intelligently ;

6.High quality cost performance.

| Compare Item 1 | Navies pad | silicone pad | Compare Item 2 | Navies pad | silicone pad |

| Life | ◎ | ▲ | Homogeneity of dielectric layer | ◎ | ◯ |

| Pressure buffering | ◎ | ◯ | Impedance controllability | ◎ | ◯ |

| Pressure uniformity | ◎ | ▲ | Plate thickness uniformity | ◎ | ◎ |

| Pressure transfer stability | ◎ | ▲ | Thick copper adaptability | ◎ | ▲ |

| Heat buffering | ◎ | ◎ | Chip cost | ◎ | ▲ |

| Heat transfer uniformity | ◎ | ◎ | Storage convenience | ◎ | ▲ |

| Heat conduction efficiency | ◎ | ▲ | Operation convenience | ◎ | ▲ |

| Processing efficiency | ◎ | ◯ | Cleanliness | ◎ | ▲ |

| Heat resistance | ◎ | ◯ | Recycling and reuse | ◯ | ◎ |

| Moisture resistance | ◎ | ▲ | Cost-effective | ◎ | ▲ |

◎:Excellent ◯:Good ▲:Poor

Proven Results: Backed by a track record of 10–20% cost reductions across diverse industries.

Customized solutions designed to address your specific operational challenges.

Beyond immediate savings, our products enhance efficiency, productivity, and sustainability.

By partnering with us, customers not only reduce costs but also gain a competitive edge through improved performance, reliability, and environmental compliance. Our cost-saving solutions are a strategic investment in your business’s future, delivering measurable financial benefits and operational excellence.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More