Product introduction

1.The Press Pad boasts outstanding buffering performance. When compared with the kraft paper commonly used in lamination processes, its shock - absorption and buffering performance stands out significantly, leading that of kraft paper by 12%, thus helping to make your lamination process more perfect.

2. As a "capable assistant" in high - temperature fields, the Press Pad contains high - temperature - resistant lamination pad materials, endowing it with extraordinary endurance. A high temperature of 280°C is like a routine for it. It can operate continuously, has excellent heat - conduction performance and uniform heat absorption, fully unlocking the potential of the production efficiency of high - temperature lamination.

3. From raw materials to finished products, the Press Pad undergoes the baptism of repeated pressing and polishing on the production line. This perseverance and dedication are translated into the ultimate consistency of uniform and flat thickness, ensuring the smooth progress of every step of your process.

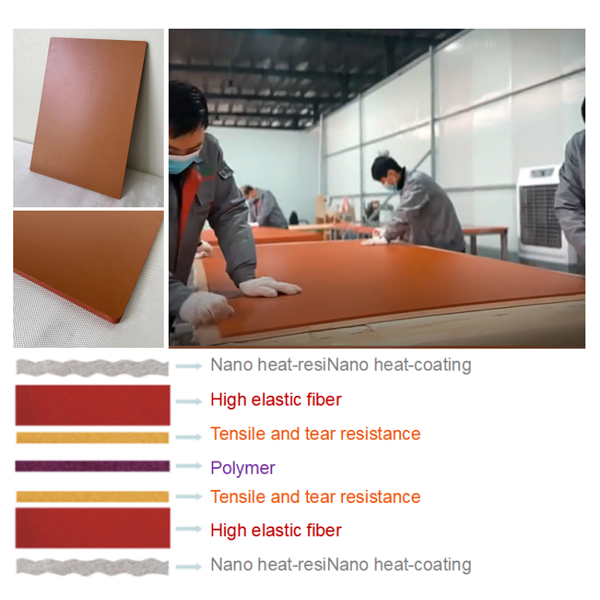

Component

The meticulously crafted Press Pad is compounded by integrating the flexibility of high - elastic fibers, the toughness of anti - sticking and high - temperature - resistant reinforcement materials, and the compatibility of high - molecular polymers.

The Press Pad is crafted by integrating high-elastic fibers for flexibility, anti-sticking and high-temperature-resistant reinforcement materials for toughness, and high-molecular polymers for compatibility.

Feature and Application

It is mainly used in the lamination processes of CCL, aluminum - based substrates, furniture panels, PCB, HDI, high - frequency and high - speed boards, FCCL, solar panels, liquid - crystal panels, etc. At present, it is the best product to replace kraft paper and silicone pads.

Wide Range of Applications

Used in the lamination of CCL, aluminum-based substrates, furniture panels, PCB, HDI, high-frequency boards, FCCL, solar panels, and liquid-crystal panels, it is the best alternative to kraft paper and silicone pads.

The Press Pad shines differently in various industries. In the electronics manufacturing field, during the circuit - board lamination process, it is like a loyal guard. With its excellent buffering performance, it protects electronic components, and its high - temperature resistance enables it to remain stable in high - temperature processes, ensuring the smooth production of electronic products. In the furniture manufacturing field, it transforms into a "bonding master". It enables various types of boards to be closely and smoothly laminated. The problems of laminating multi - layer plywood and decorative boards are easily solved, enhancing the competitiveness of furniture products. In the automotive interior production workshop, when dashboards, door interior panels, etc. are formed under high temperature and high pressure, it provides precise buffering, resists heat and prevents wrinkling, adding points to the quality of automotive interiors. In the packaging and printing industry, for the lamination and film - covering of hard - cover book covers and high - end packaging boxes, it provides buffering support, protects the graphics and text, and promotes bonding, helping to create high - end packaging. In the photovoltaic industry, during the encapsulation and lamination of solar panels, it adapts to high temperatures, ensures the stability of solar cells, and guarantees the efficient power generation of photovoltaic modules.

1.Electronics Manufacturing

Protects electronic components during circuit-board lamination, ensuring stable performance in high-temperature processes.

2.Furniture Manufacturing

Enables tight and smooth lamination of multi-layer plywood and decorative boards, enhancing furniture quality and competitiveness.

3.Automotive Interior Production

Provides precise buffering and heat resistance during the formation of dashboards and door panels, improving the quality of automotive interiors.

4.Packaging & Printing

Supports the lamination and film-covering of hardcover book covers and high-end packaging boxes, ensuring high-quality results.

5.Photovoltaic Industry

Ensures stability during the encapsulation and lamination of solar panels, guaranteeing efficient power generation.

Why Choose PCB Press Pad?

ü Enhanced Efficiency

Reduces production downtime and improves lamination precision.

ü Cost-Effective

Replaces single-use materials like kraft paper, lowering operational costs.

Durable & Reliable

Withstands high temperatures and repeated use without compromising performance.

Service quality assurance : Ensure that service providers have the professional skills and good attitude to provide high-quality services. Timely response and solve problems, for customer problems and needs, service support personnel should respond in a timely manner and give effective solutions.

More